Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

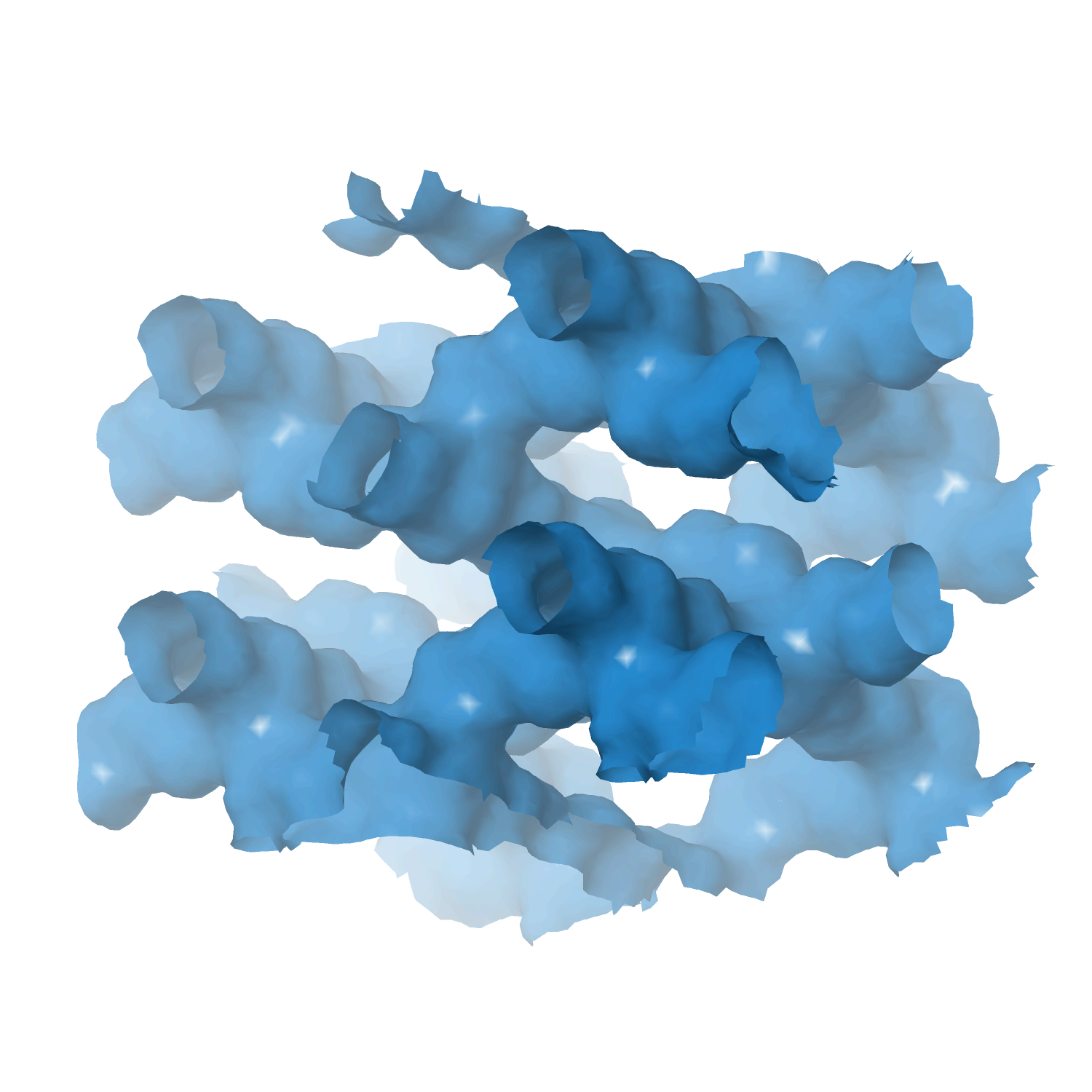

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Upgrading Model Compounds and Scrap Tires Pyrolysis Oil (STPO) on Hydrotreating NiMo Catalysts with Tailored Supports

by

Hita, Gutierrez, Olazar, Bilbao, Arandes, Castaño

Fuel

Year:

2015

Abstract

The upgrading of Scrap Tire Pyrolysis Oil (STPO) has been studied in order to remove undesired sulfur, nitrogen and unsaturated compounds while improving the properties of its different fractions (naphtha, diesel and gasoil) toward being used as a potential blend in the refinery. The studied catalysts are NiMo supported on 5 porous materials: γ-Al2O3 (ALM catalyst), SiO2–Al2O3 (ASA), SBA-15 (SBA), MCM-41 (MCM) and an equilibrated FCC catalyst (FCC). The hydrotreating runs have been carried out in a fixed bed reactor at 275–375 °C and 65 bar. The catalysts were characterized by ICP-AES, N2 adsorption–desorption isotherms, H2 chemisorption, XRD, XPS, TPR and terc-butylamine adsorption–desorption (TPD). A preliminary catalyst screening with a model mixture of representative STPO compounds has been performed for selecting the most active catalysts: ALM, ASA and MCM catalysts ensured the 99.9% removal of sulfur. Secondly and in the hydrotreating of STPO, our results point the suitability of ASA catalyst for obtaining the highest proportion of naphtha (25 wt%) and diesel (57 wt%), ALM catalyst for increasing the yield of paraffins and the cetane number in diesel, and the promising performance of MCM catalyst for facilitating internal mass transfer.

Keywords

HPC

W2C

ANW

HCE