Asphaltenes in crude oil are high–molecular–weight, polyaromatic, heteroatom-containing compounds that cause serious operational problems in petroleum production and refining, such as fouling, catalyst deactivation, and yield losses. Traditional solvent de-asphalting (SDA) processes effectively remove asphaltenes but require extensive solvent circulation, high energy for solvent recovery, and produce low-value pitch byproducts.

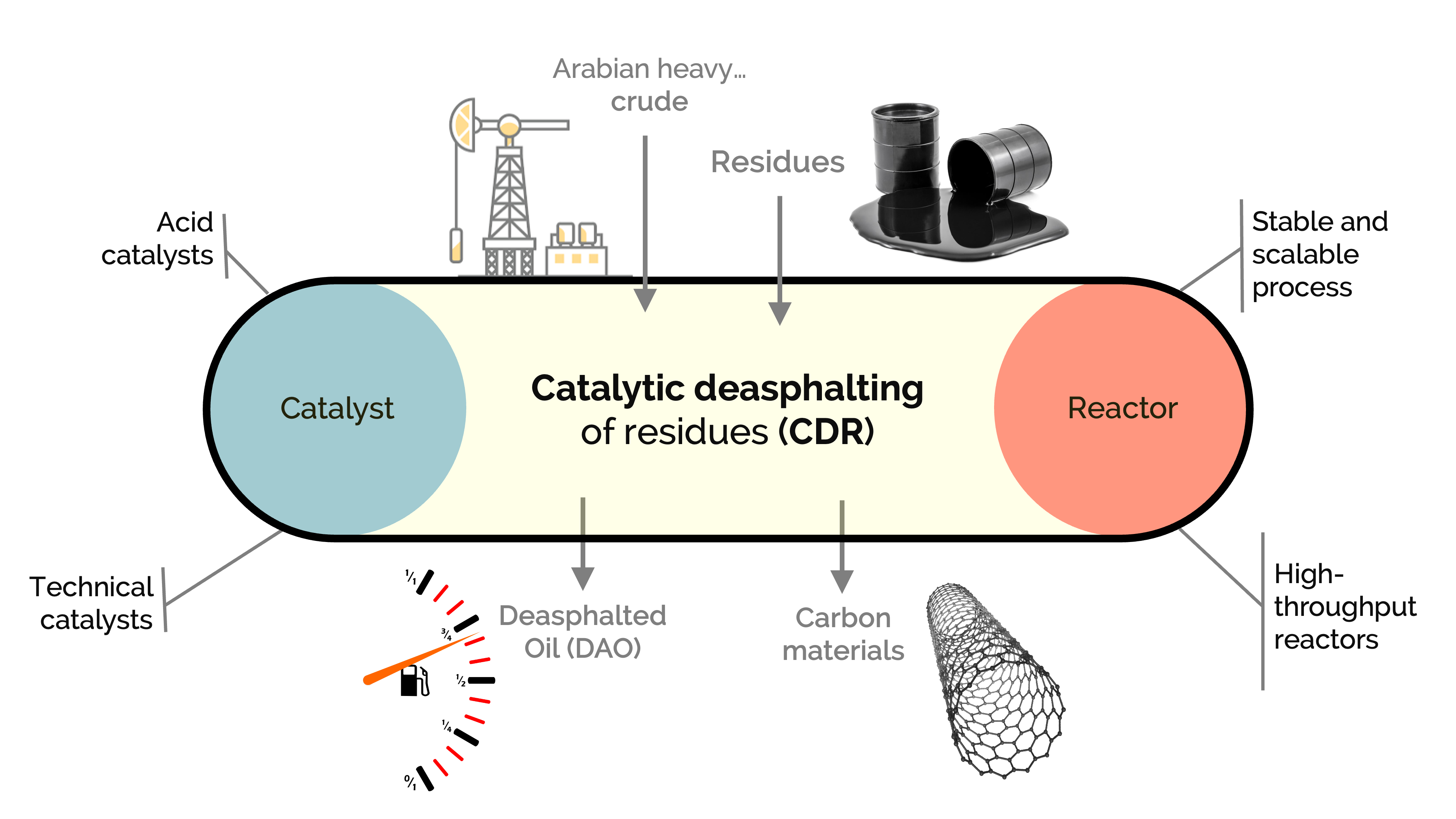

This project aims to develop a non-solvent, catalyst-based de-asphalting process using acid catalysts and other solid acids, thereby avoiding solvent waste, lowering operating costs, and enabling production of higher-value products.

The approach includes catalyst testing, process optimization, mechanistic studies, and preliminary scale-up design. Our work covers the fundamentals of catalyst selection and mechanistic pathways for asphaltene precipitation, through laboratory process optimization, advanced analytics for product characterization, and process modeling for continuous operation and scale-up.