The vision of MuRE is to contribute to a chemical industry based on sustainability, circularity, and green chemistry principles. We aspire to help the Kingdom of Saudi Arabia and the world transition from an oil-based economy to a circular one following the hierarchy: intensifying the current refinery downstream operations, incorporating alternative and waste feedstock into the production chains, and developing innovative catalytic processes.

Given the applied nature of our goals, we cooperate extensively with industry and government stakeholders.

| The mission of MuRE is to

engineer advanced catalytic reaction systems that harness the power of surfaces, pores, heat, microorganisms, electrons, and photons to accelerate and make more efficient

chemical transformations. Our research integrates experimental and computational methods to advance catalytic reaction engineering at multiple scales, from molecular interactions to reactor-scale processes

.

|

We target processes that address the energy transition and sustainability challenges: decarbonization,

circularity, process intensification, energy security, waste valorization, pollutant removal, among others. These are transformations of small molecules (carbon dioxide, methane, ammonia, alkanes,

methanol) or bulkier ones in complex mixtures (refinery residues, crude, biomass, lignin, plastic wastes, used tires) into hydrogen, light olefins/alkenes, platform chemicals or high-quality fuels. We investigate

these chemistries at different levels/scales: molecular, catalyst, and reactor scale.

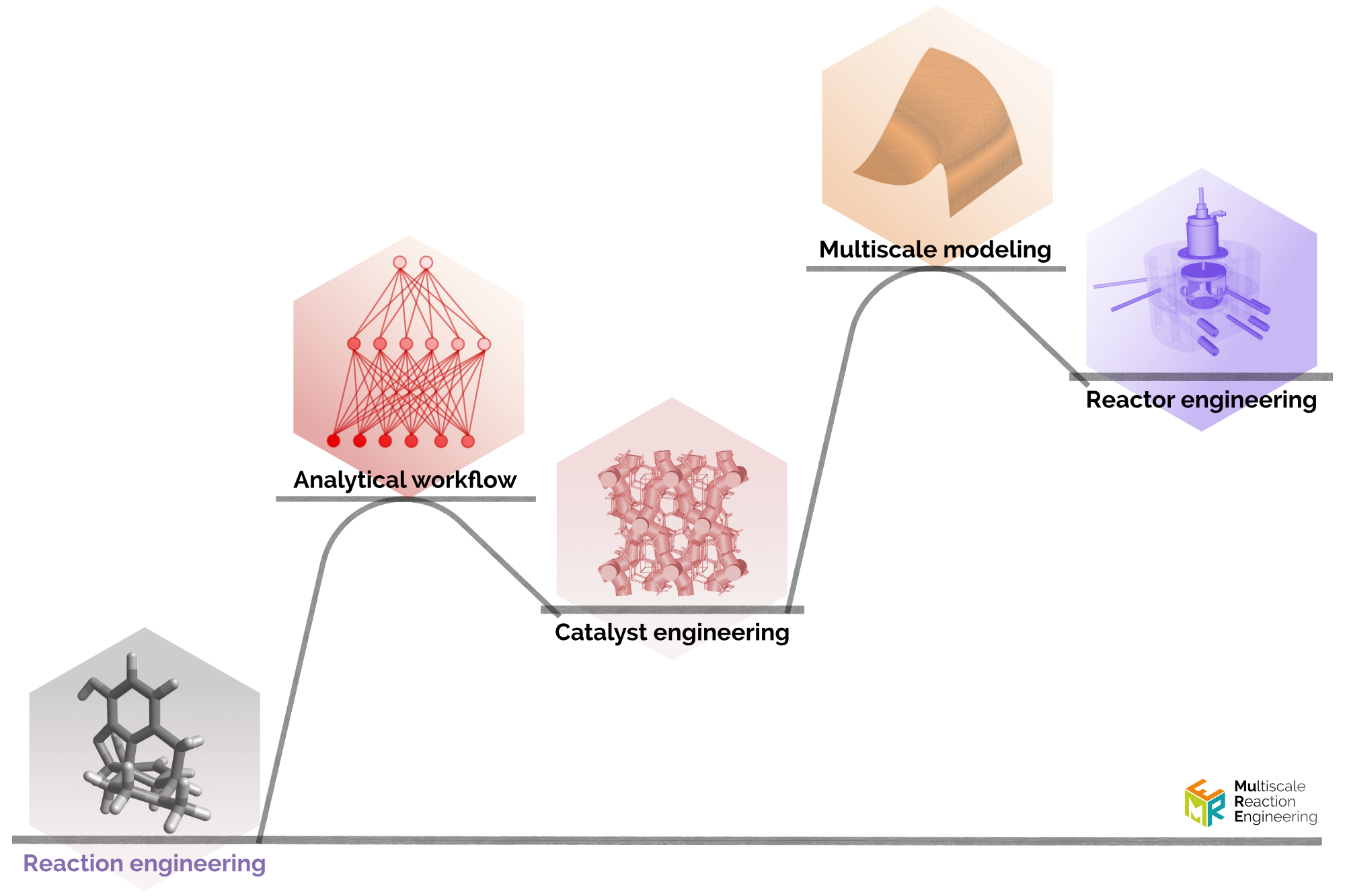

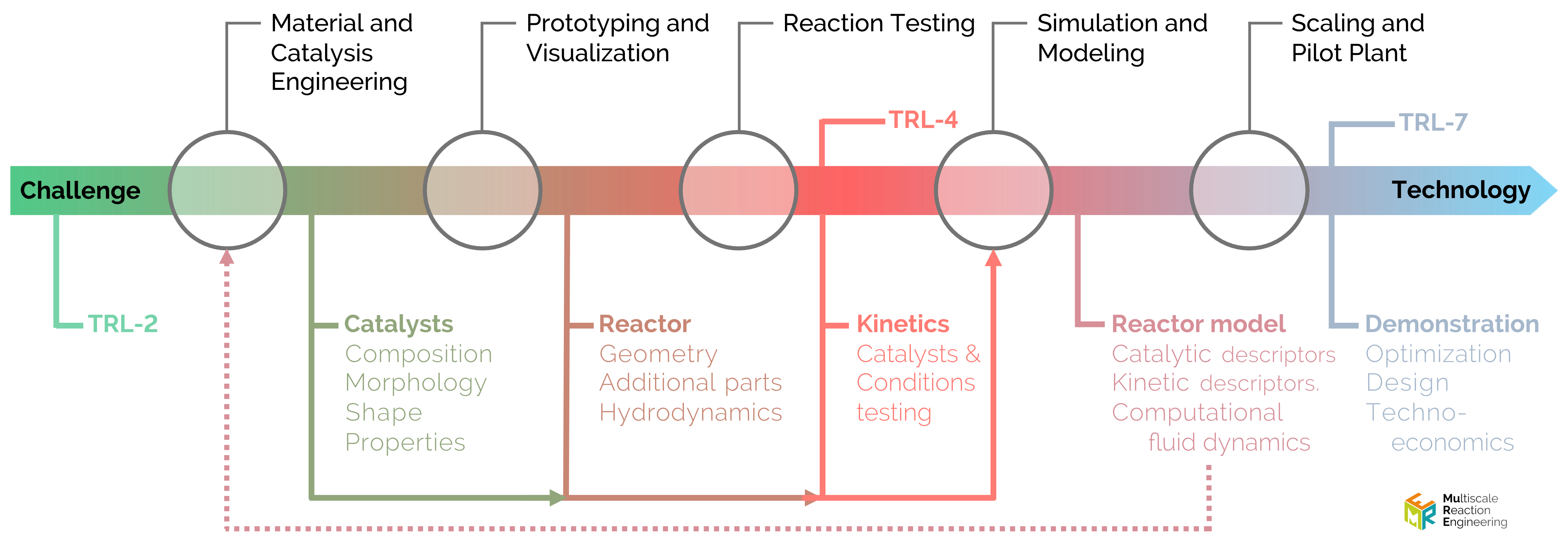

Our key competencies are under the umbrella of catalytic reaction engineering:

Analytical workflow: Complex reaction networks considering the complete reaction media, including intermediates, activity modifiers (water, poisons…), complex mixtures, and trapped or deactivating species. Realistic feeds.

Catalyst engineering: Heterogeneous catalysts with multiple functionalities, particularly stability. We seek scientific understanding beyond the synthesis-related aspects to control these functionalities from the nano- to the macroscale.

Multiscale modeling: Molecular-level microkinetic and macrokinetic models. Computational fluid dynamics and computational particle fluid dynamics. Process simulations.

Reactor engineering: Information-driven and multi-functional catalytic reactors with high throughput intrinsic kinetic data and controlled hydrodynamics. These include packed (operando), fluidized beds, and multiphase reactors.

On this website, you can read the who, the how, the what,

and the where. Also, you can just read our latest news and check a list of available positions or upcoming events.