Our research is at the interface between chemical engineering, catalysis, surface kinetics, analytical, and physical chemistry. We aim to bridge the fundamental aspects of chemical reactions and catalysis with reactor design and process development. Our core competencies are:

MuRE develops reaction engineering technologies spanning catalysts, reactors, and multiscale models. Our projects integrate synthesis, shaping, testing, modeling, and scale-up to deliver deployable solutions for energy, chemical production, waste valorization, circular carbon, hydrogen production, sulfur removal, and hydrocarbon intensification, bridging fundamental chemistry with industrial reactor concepts and pilot-ready systems.

This project develops a two-stage thermo-catalytic route to upgrade algae via hydrothermal liquefaction followed by continuous catalytic hydrotreatment, while reutilizing aqueous by-products as algae growth media. The approach delivers kinetic insight, advances the process to TRL4, and enables resource circularity for sustainable bio-fuel and chemical production.

AGILE (Advanced Granulation for Industrial Layered Engineered Catalysts) is a research project focused on designing and scaling catalyst shaping routes based on advanced granulation and spray-fluidized-bed technologies. The objective is to engineer layered, mechanically robust catalyst particles with controlled porosity, composition, and accessibility, suitable for fluidized and circulating reactors.

Our CO₂RR project develops continuous-flow electrochemical cells using Cu-based electrocatalysts and dynamic conditions to convert CO₂ into C2+ products under industrially relevant conditions. It integrates catalyst design, cell engineering, and scale-up toward a pre-industrial continuous prototype.

CounterDowner™ is MuRE’s counter-current downer platform, developed from lab-scale rigs to scaled-up units. We combine a desing workflow based on computational and tools. With specific process conditions and desing we can control the hydrodynamics, solids flux, and residence-time distributions. Our technology deliver predictable gas–solid contacting across scales.

MOF④SAF (MuRE scope) focuses on scaling up Cu/ZIF-8 catalysts for thermocatalytic CO₂-to-SAF pathways. The work covers reproducible synthesis, shaping, and stability under operation, linking materials engineering with reactor-scale performance. Emphasis is placed on scale-up rules, durability, and transfer from the lab to industrial implementation.

C1R develops forced dynamic and operando catalytic reactors to accelerate mechanism and kinetic discovery in C1 chemistries. It targets CO₂ hydrogenation and dry reforming of methane by coupling catalyst dynamics, reactor modulation, and multi-technique operando analysis under industrially relevant conditions.

CircuBED™ is MuRE’s internally developed Berty-type circulating fluidized-bed reactor for intrinsic kinetics under realistic solids circulation. It enables controlled gas–solid contact, rapid heat and mass transfer, and on-line switching between batch and continues regimes, bridging precise contact, kinetics and performance.

CDR (Catalytic Deasphalting of Residues) is a project targeting the selective conversion of asphaltene-rich refinery residues into lighter fractions using tailored catalysts and advanced reactor concepts. The program integrates kinetics, catalyst deactivation, and hydrodynamics to enable continuous operation, residue upgrading, and higher carbon utilization with reduced fouling risk.

CLEAR-bio (Continuous Loop Electrochemical Airlift bioreactor) is a MuRE project developing an annular, zero-gap bioelectrochemical reactor for energy-aware wastewater treatment. The concept integrates airlift-driven circulation, controlled hydrodynamics, and low internal resistance to achieve stable COD removal and electricity generation, with clear design and scale-up rules from lab to pilot.

HYDRA-S (HYdrogen from the Decomposition and Reforming of Acidic Hydrogen Sulfide) is a project targeting catalytic dissociation of H₂S into hydrogen and elemental sulfur. The program integrates catalyst design, kinetics, and reactor engineering to enable stable, continuous operation under relevant conditions, addressing deactivation and sulfur handling while defining scale-up rules for industrial hydrogen production from sour streams.

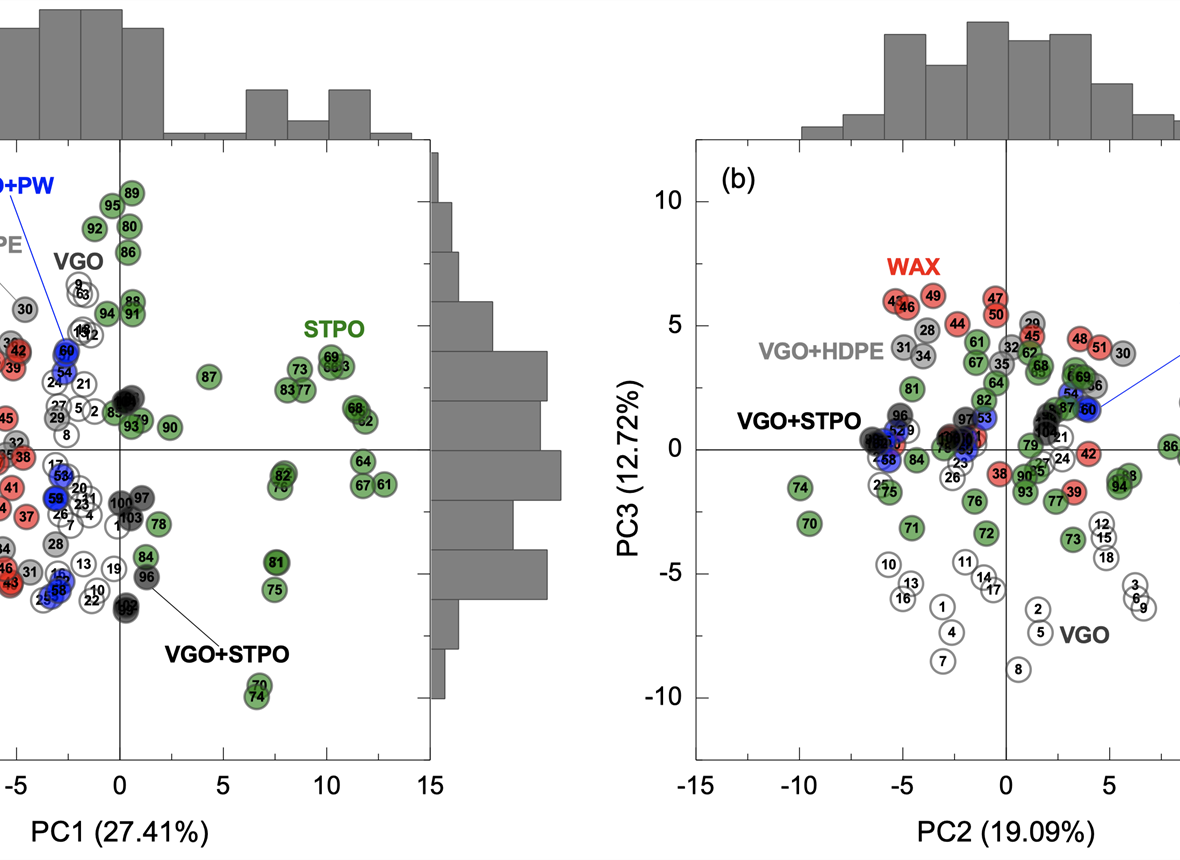

Wasteomics develops molecular-level understanding of municipal solid waste thermo-catalytic valorization. It integrates advanced analytics, miniaturized pyrolysis–catalysis reactors, data-mining, reactive molecular dynamics, and microkinetic modeling to map reaction networks, char and coke formation, and guide catalyst and process design for scalable chemical recycling across heterogeneous feeds and variable operating conditions globally.

MuRE contributes to a QNRF project (in collaboration wiht Qatar) through the design, optimization, and scaling of microbial fuel cells. Our role focuses on converting industrial wastewater into electricity using advanced electrodes, supplying sustainable power to the integrated system. The overall project targets efficient lithium recovery from low-grade brines via coupled electrochemical processes.

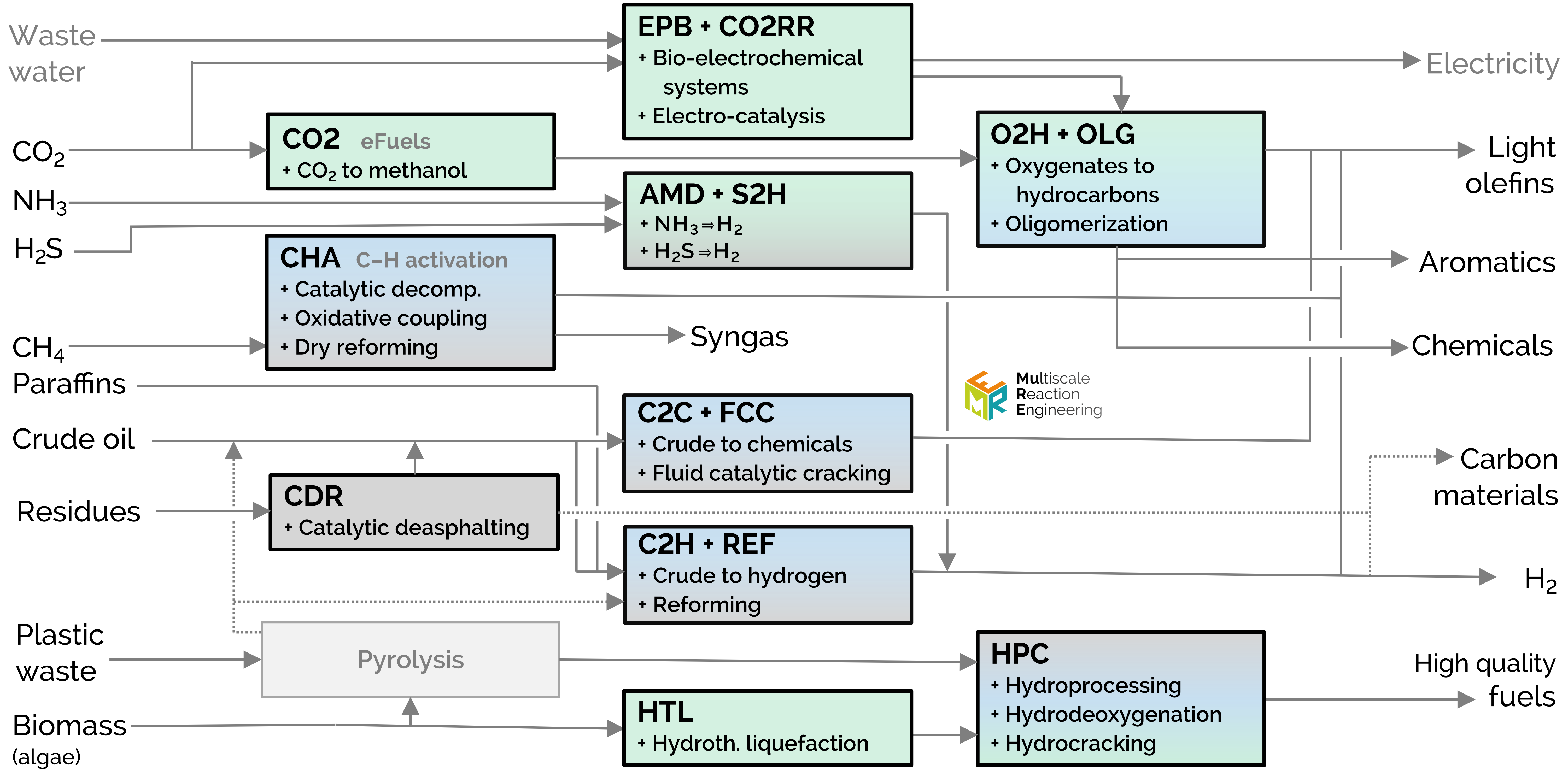

The catalytic processes we investigate fall into (1) hydrocarbon sustainability, (2) alternative feedstock and (3) circular carbon economy and waste-valorization, such as the transformations of small molecules (carbon dioxide, methane, ammonia, alkanes, methanol) or bulkier ones in complex mixtures (refinery residues, crude, biomass, lignin, plastic wastes, used tires) into hydrogen, light olefins/alkenes, platform chemicals or high-quality fuels.

Below is an overall scheme of processes we investigate and more details about them, who works here, and our publications.

Modeling and scaling processes to generate high-pressure hydrogen (H₂) from ammonia

Process development for the deasphalting of crude and residues using heterogeneous catalysts

Stable catalyst design for the viable activation of methane to syngas, hydrogen, and chemicals

Towards a feasible and stable thermocatalytic conversion of CO₂ to methanol and E-fuels

Reactor design and optimization for converting crude (and refinery wastes) to chemicals in one step through steam-fluidized catalytic cracking

Process development and deployment for the direct reforming of crude oil to hydrogen and carbon materials

Design and development of unconventional catalytic conversion processes using electrons, photons, and microorganisms

Upgrading renewables, secondary, and waste streams through innovative hydroprocessing catalysts and reaction pathways

Designing sustainable routes to produce fuels and chemicals from algae trough catalytic liquefaction

Controlling selectivity and stability of zeolite catalysts for methanol to hydrocarbons and ethylene oligomerization