Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

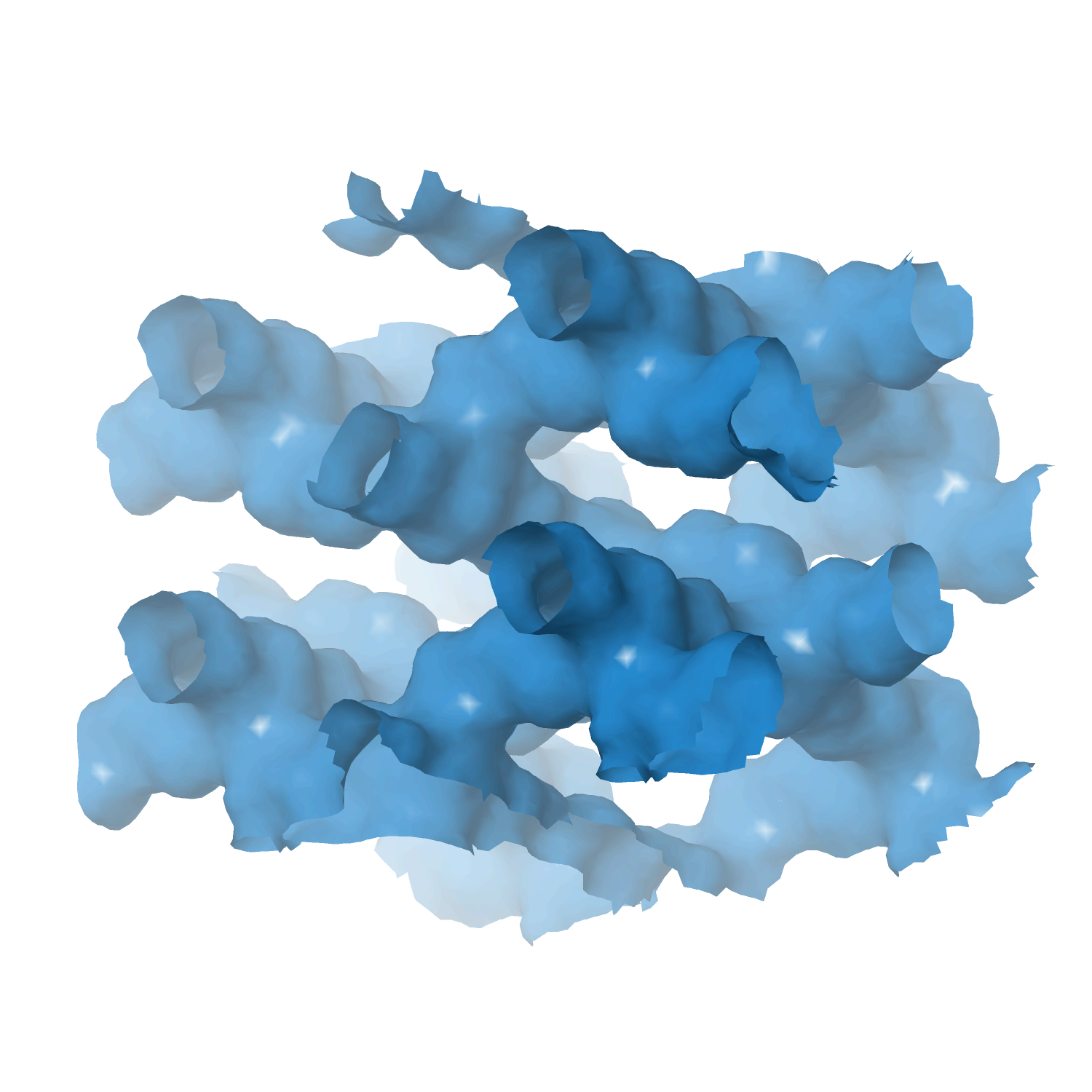

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

The Role of Zeolite Acidity in Coupled Toluene Hydrogenation and Ring-Opening in One and Two Steps

by

Castaño, Pawelec, Aguayo, Gayubo, Arandes

Ind. Eng. Chem. Res.

Year:

2008

Abstract

In this work, the effect of HZSM-5 zeolite acidity on hydroconversion of methylcyclohexane and toluene has been studied. These are test reactions for the second step and the single step of aromatic valorization process, respectively, with the aim of obtaining C2+n-alkanes and isoalkanes. Monofunctional HZSM-5 zeolite catalysts (Si:Al ratio between 15 and 140) have been studied in methylcyclohexane ring opening while bifunctional catalysts (hybrid Pt/Al2O3-HZSM-5, same zeolites) have been used in the hydrocracking of toluene. Runs have been carried out in a fixed bed reactor under 250−450 °C and 20−80 bar. A positive effect of HZSM-5 zeolite acidity on methylcyclohexane conversion and C2+n-alkane selectivity is evident at certain conditions, whereas the maximum selectivity to isoalkanes requires an intermediate value of acidity. On the basis of the relationship between conversion and the Si:Al ratio of the HZSM-5 zeolite, the hydrogenolytic cracking of methylcyclohexane is proposed as a test reaction to determine the Si:Al ratio. Acidity has a highly favorable effect in the hydrocracking of toluene given that it avoids the thermodynamic restrictions for toluene hydrogenation and enhancing all the cracking steps during methylcyclohexane (MCH) transformation, which increases selectivity to C2+n-alkanes and isoalkanes.

Keywords

HCE

HPC

FCC