Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Selectivity and Microkinetic Insights on Ethylene Oligomerization over Ni Encapsulated in a Brønsted-less Hollow ZSM-5 Zeolite

by

Abed, Mohamed, khairova, Hita, Velisoju, Morlanes, Meijerink, Emwas, Vernuccio, Castaño

ChemCatChem

Year:

2025

DOI:

https://doi.org/10.1002/cctc.202500957

Abstract

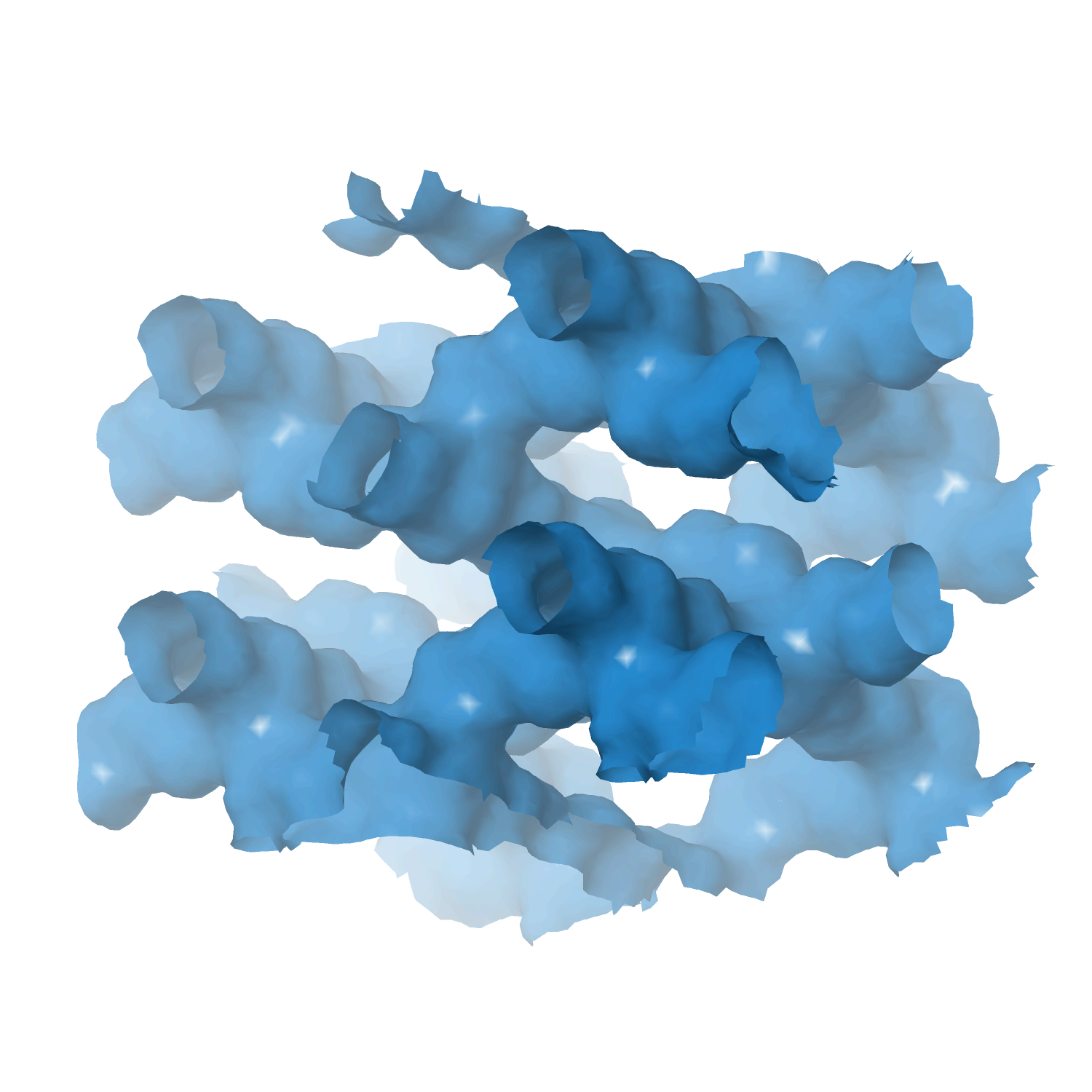

We encapsulated Ni nanoparticles in a hollow ZSM-5 zeolite catalyst using the dissolution-recrystallization method to catalyze ethylene oligomerization. Our aim is to engineer an idealized catalyst free of Brønsted acid contributions to kinetics or deactivation, having isolated and encapsulated Ni2⁺–zeolite species, to study the intrinsic oligomerization kinetics on Ni2⁺–zeolite through an experimental and microkinetic standpoint. We proved how the hollow architecture encapsulates both Ni2⁺ and NiO species, being the former significantly more active and selective toward dimerization. A comprehensive microkinetic model, grounded in the Cossee-Arlman mechanism and parameterized using experimental data, provides a detailed understanding of the reaction network on isolated Ni2⁺ sites. The model reveals that while linear butene formation dominates, its selectivity decreases with increasing ethylene conversion, temperature, and pressure, highlighting the contribution of isomerization pathways at elevated temperatures. This study focuses on the method to develop isolated oligomerization sites and then studies the intrinsic microkinetic pathways and rates.

Keywords

OLG

MKM

HCE