Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

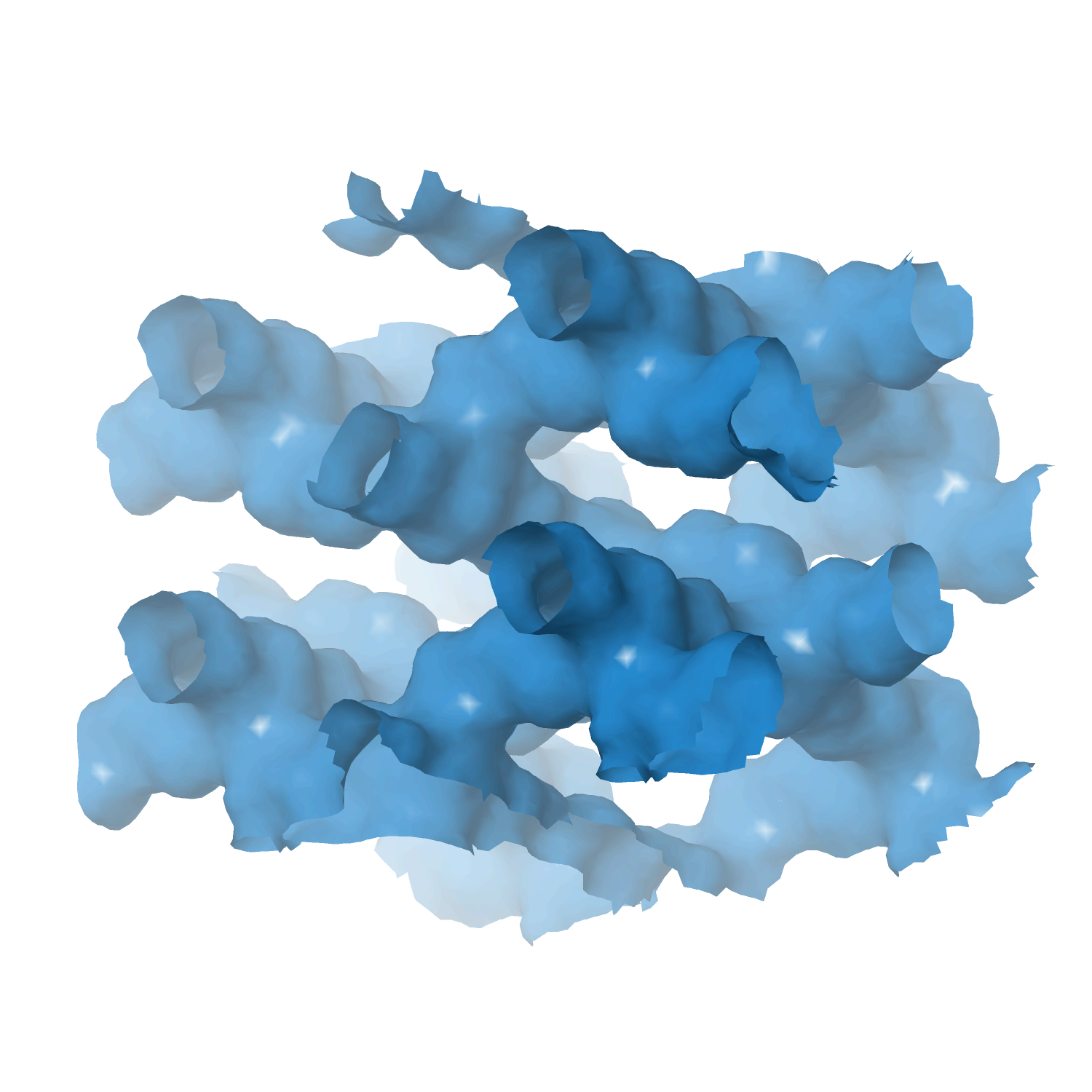

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Role of the Ru and Support in Sulfided RuNiMo Catalysts in Simultaneous Hydrodearomatization (HDA), Hydrodesulfurization (HDS), and Hydrodenitrogenation (HDN) Reactions

by

Pawelec, Navarro, Castaño, Alvarez-Galvan, Fierro

Energy & Fuels

Year:

2009

Abstract

Simultaneous hydrodesulfurization (HDS), hydrodearomatization (HDA), and hydrodenitrogenation (HDN) reactions have been studied over sulfided RuNiMo/Al2O3 catalysts. The effects of Ru promotion and alumina support modification with HY zeolite and P on catalyst performance have been studied using a synthetic feed containing dibenzothiophene, toluene, naphthalene, and pyridine. Activity tests were carried out in a semi-automatic microplant equipped with a continuous flow reactor, working under conditions similar to industrial practice (P = 5 MPa, T = 285−360 °C, and liquid hourly space velocity (LHSV) = 3 and 4.5 h−1). The catalysts were characterized by SBET, X-ray diffraction (XRD), temperature-programmed reduction (TPR), temperature-programmed desorption of ammonia (TPD−NH3), and X-ray photoelectron spectroscopy (XPS) techniques. Activity tests revealed that optimal Ru loading is 1 wt % (nominal). Under fixed experimental conditions (300 °C, 5 MPa, and LHSV = 3 h−1), ultra-low sulfur diesel (S < 20 ppm S) was obtained over a Ru(1%)Ni(5%)Mo(14%)/γ-Al2O3 catalyst from a feed containing 18361 ppm S. However, this catalyst showed similar capability toward aromatics and pyridine removal as a commercial NiMo/Al2O3 catalyst. At a reaction temperature of 345 °C, the 5% HY−Al2O3 substrate led to a small increase in the hydrogenation capability of this catalyst but without enhancement of its HDS/HDN capability. On the contrary, the P-modified substrate resulted in a lower activity. The properties of the supported catalysts are discussed in terms of the support effect and Ru promotion.

Keywords

HCE

HPC