Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

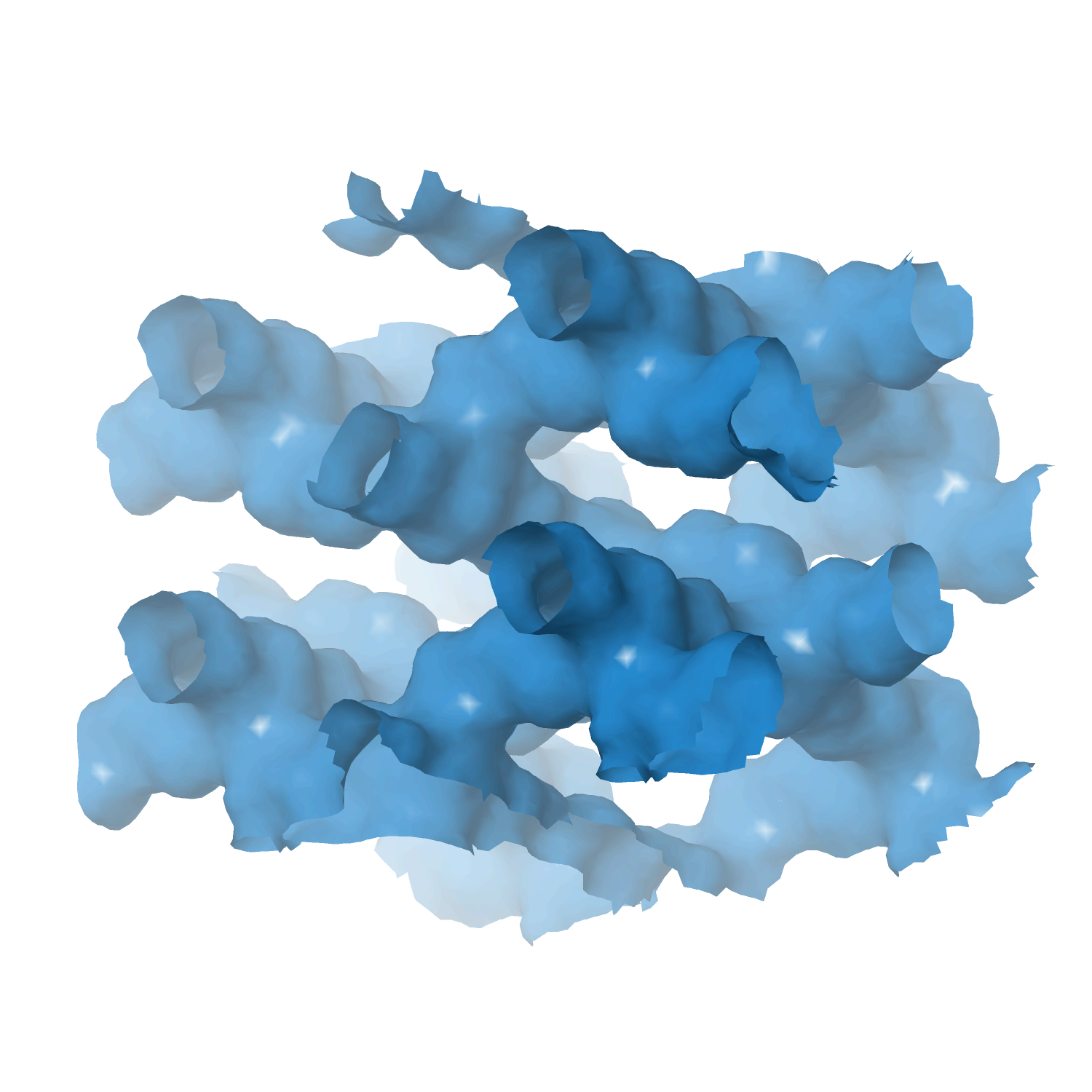

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Outstanding performance of direct urea/hydrogen peroxide fuel cell based on precious metal-free catalyst electrodes

by

Eisa, Park, Mohamed, Abdelkareem, Lee, Yang, Castaño, Chae

Energy

Year:

2021

Abstract

Direct urea/hydrogen peroxide fuel cells (DUHP-FCs) can produce electrical energy by recycling urea-rich wastewater. This study expands the commerciality of DUHP-FC by removing precious metals from their design. Nickel nanorod/nickel foam (NNR/NF) was fabricated using hydrothermal treatment to be used as the anode, and Prussian blue coating was deposited by potentiostatic electrodeposition onto hydrophilic carbon felt at the cathode (PB/CF). The anode exhibited a 7-folds higher current density than bare NF at 0–2 M urea, and lower charge transfer resistance. The cathode reported a high H2O2 reduction current. In addition, fuel cell tests indicated current density dependency on H2O2 concentration and cell voltage dependency on KCl concentration. A competitive maximum power density of 10.6 mW cm−2 was achieved at 0.98 open circuit voltage and 45 mA cm−2 maximum current density, in 0.33 M urea vs 2 M KCl and 2 M H2O2, exclusively via diffusive mass transfer. These findings indicate the practical application of DUHP-FC on a large scale.

Keywords

EPB

HCE