Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Microbial symbiotic electrobioconversion of carbon dioxide to biopolymer (poly (3-hydroxybutyrate)) via single-step microbial electrosynthesis cell

by

Le, Mohamed, Kim, Yoo, Eisa, Jadhav, Nguyen, Eam, Myung, Castaño, Chae

Chem. Eng. J.

Year:

2024

DOI:

https://doi.org/10.1016/j.cej.2024.156635

Abstract

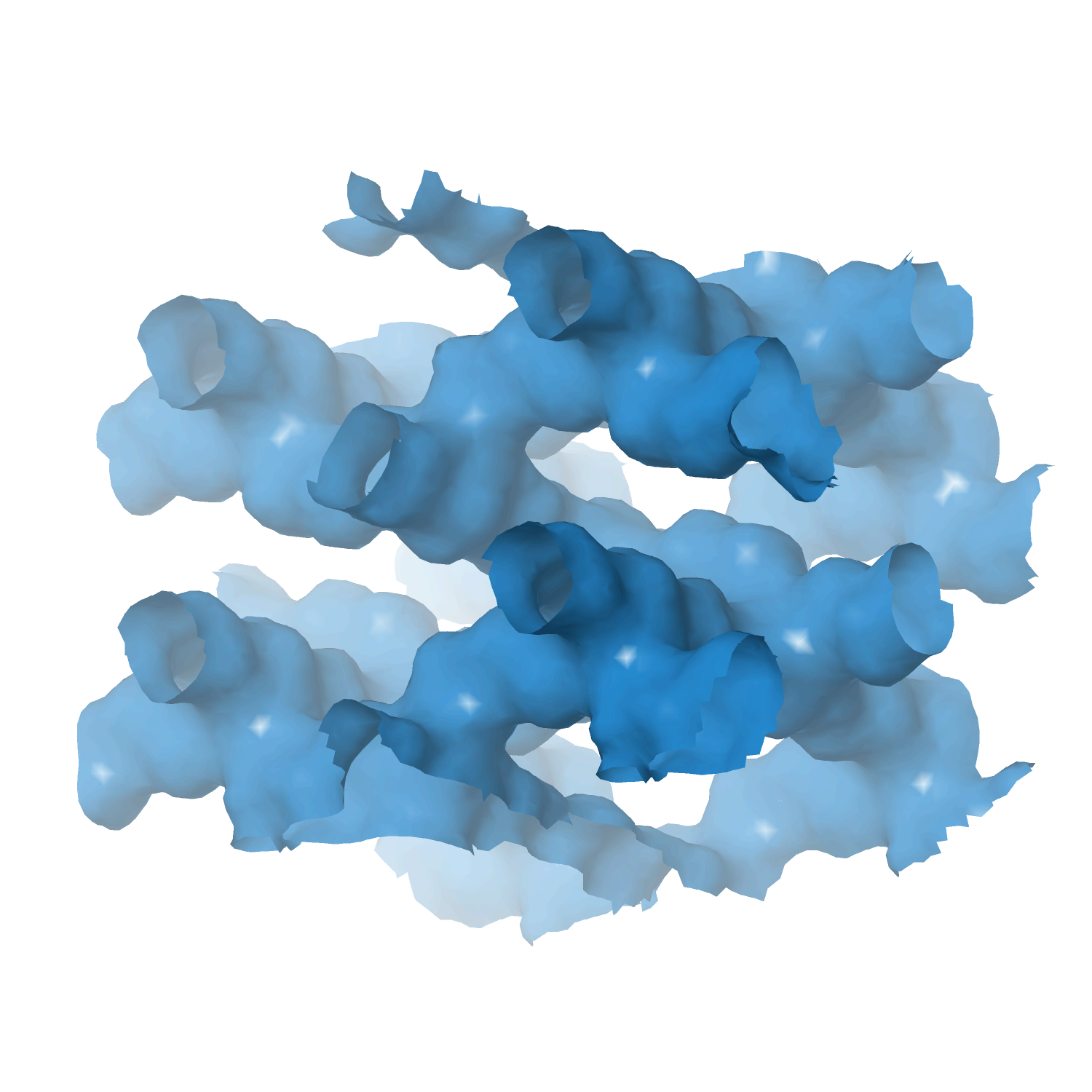

This study proposes an novel single-stage microbial electrosynthesis system (MES) that bioelectrochemically converts CO2 into poly(3-hydroxybutyrate) (PHB). This innovative approach utilizes a symbiotic co-culture of electroactive acetogenic bacteria and PHB-accumulating bacteria within a single reactor, bypassing the need for separate acetate production and extraction. Systematic optimization of key operational parameters, including applied voltage, carbon source, and cathode material, was conducted to maximize PHB production. Results demonstrate that using a voltage of 2.5 V yielded a 7.14-fold increase in PHB content compared to open circuit conditions. Furthermore, functionalizing the cathode with a conductive and hydrophilic PEDOT: PSS polymer coating significantly enhanced the system’s performance, resulting in a 1.5-fold increase in both acetate and PHB production compared to unmodified carbon felt electrodes. The long-term stability and effectiveness of the co-culture system were validated through comprehensive microbial and metagenomic analyses. Results revealed a significant enrichment of CO2-utilizing electrotrophs within the cathode biofilm, including Acetobacterium and Clostridium. Concurrently, a 4 to 14-fold increase in the relative abundance of PHB-biosynthesizing bacteria, such as Pseudomonas, Rhodobacter and Caulobacter was observed in the planktonic phase. This study offers a promising pathway towards a circular bioeconomy by enabling the valorization of CO2 into valuable bio-based products via single-stage MES, utilizing a symbiotic co-culture.

Keywords

EPB

HCE

CO2