Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Maximizing Active Fe Species in ZSM-5 Zeolite Using Organic-Template-Free Synthesis for Efficient Selective Methane Oxidation

by

Cheng, Yao, Zheng, Wang, Emwas, Castaño, Ruiz-Martinez, Han

J. Am. Chem. Soc.

Year:

2023

DOI:

https://doi.org/10.1021/jacs.2c13351

Abstract

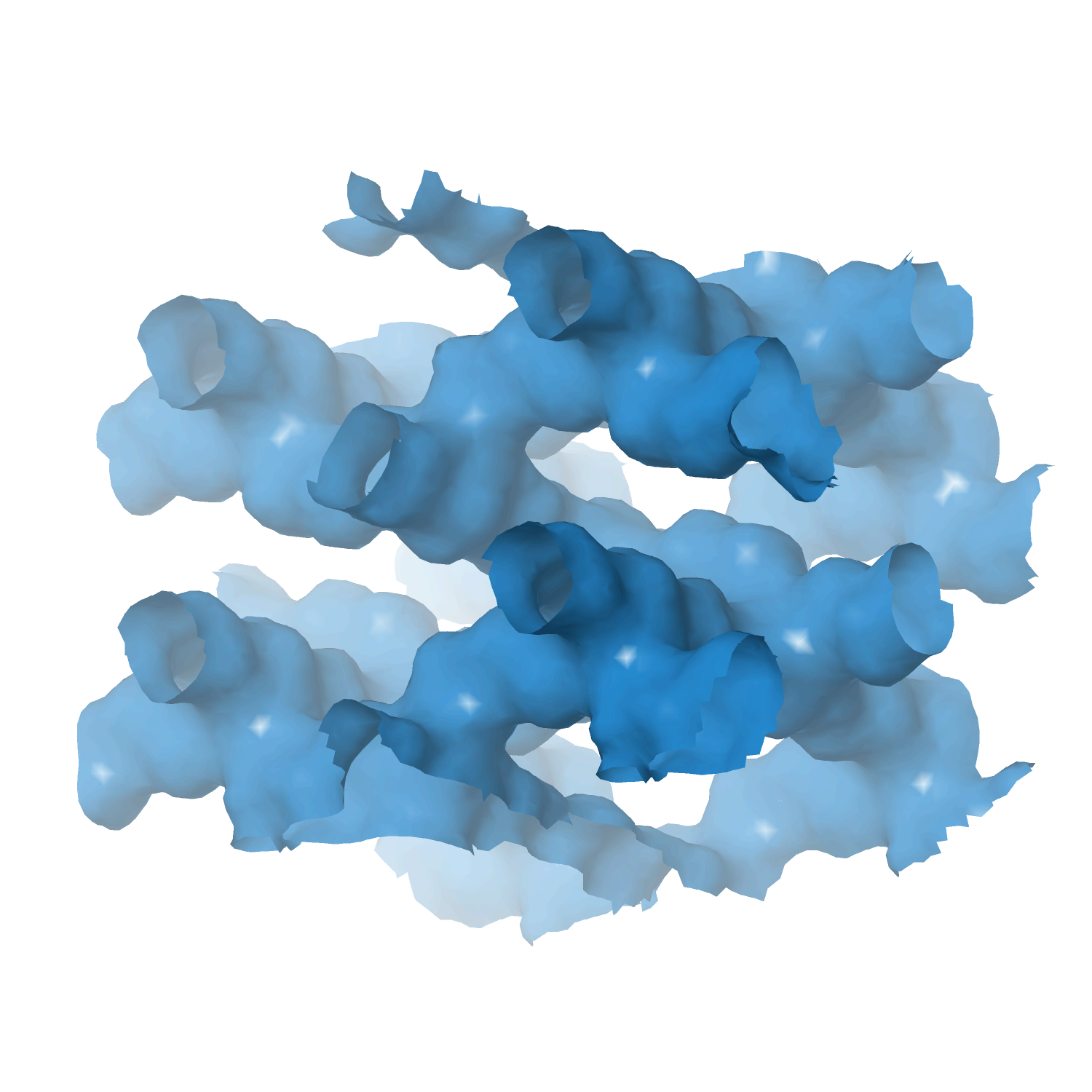

The selective oxidation of CH4 in the aqueous phase to produce valuable chemicals has attracted considerable attention due to its mild reaction conditions and simple process. As the most widely studied catalyst for this reaction, Fe-ZSM-5 demonstrates high intrinsic activity and selectivity; however, Fe-ZSM-5 prepared using conventional methods has a limited number of active Fe sites, resulting in low CH4 conversion per unit mass of the catalyst. This study reports a facile organic-template-free synthesis strategy that enables the incorporation of more Fe into the zeolite framework with a higher dispersion degree compared to conventional synthesis methods. Because framework Fe incorporated in this way is more readily transformed into isolated extra-framework Fe species under thermal treatment, the overall effect is that Fe-ZSM-5 prepared using this method (Fe-HZ5-TF) has 3 times as many catalytically active sites as conventional Fe-ZSM-5. When used for the selective oxidation of CH4 with 0.5 M H2O2 at 75 °C, Fe-HZ5-TF produced a high C1 oxygenate yield of 109.4 mmol gcat–1 h–1 (a HCOOH selectivity of 91.1%), surpassing other catalysts reported to date. Spectroscopic characterization and density functional theory calculations revealed that the active sites in Fe-HZ5-TF are mononuclear Fe species in the form of [(H2O)3Fe(IV)═O]2+ bound to Al pairs in the zeolite framework. This differs from conventional Fe-ZSM-5, where binuclear Fe acts as the active site. Analysis of the catalyst and product evolution during the reaction suggests a radical-driven pathway to explain CH4 activation at the mononuclear Fe site and subsequent conversion to C1 oxygenates.

Keywords

CHA

HCE