Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

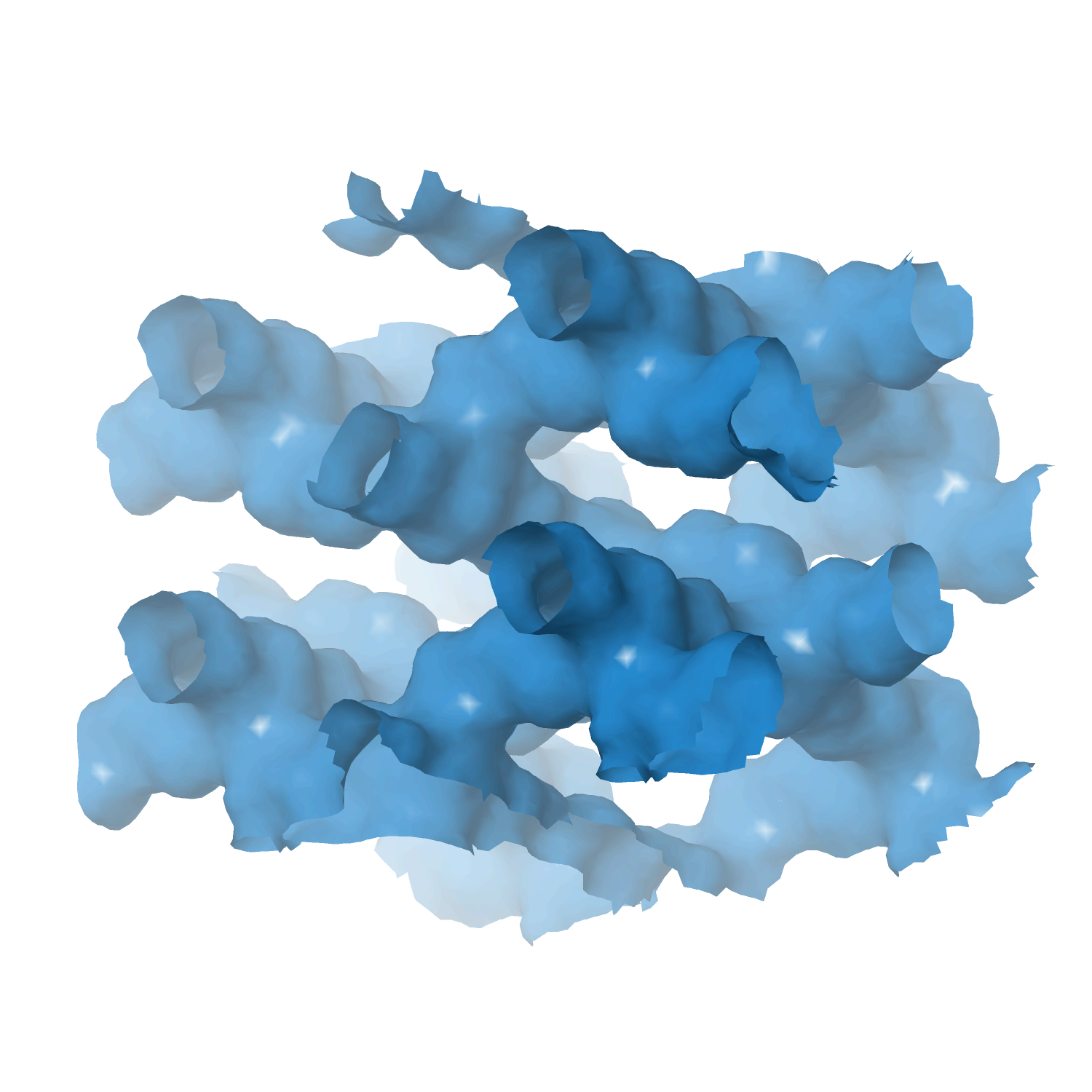

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Hydrodesulfurization of Dibenzothiophene and a SRGO on Sulfide Ni(Co)Mo/Al2O3 Catalysts. Effect of Ru and Pd Promotion

by

Navarro, Castaño, Alvarez-Galvan, Pawelec

Catal. Today

Year:

2009

Abstract

Commercial Ni(Co)Mo/γ–Al2O3 catalysts were modified by the addition of Pd and Ru in order to enhance their hydrogenation function as required for the simultaneous elimination of sulfur, nitrogen and aromatics from a gasoil. The ternary catalysts were prepared by wet impregnation of the commercial samples with Ru and Pd salt solutions. The oxide precursors were characterized by SBET, TPR, XRD, XPS and IR of adsorbed pyridine. The catalysts were tested in their sulfided forms to evaluate their activity in the hydrodesulfurization (HDS) of dibenzothiophene (DBT) and in the hydrotreating (HDT) of a straight run gas oil (SRGO; 0.11, 0.55 and 1.16 wt% of S). Catalyst screening in the HDS of DBT showed that: (i) the presence of isolated RuS2 phases located on the catalyst surface contributed to overall catalytic activity and improved the catalyst hydrogenation function, (ii) catalyst doping with Ru was more effective than its doping with Pd, (iii) maximum activity was obtained at a Ru loading of 0.5 wt%, (iv) the NiMo catalyst formulation was more effective than its CoMo counterpart, and (v) a life test (87 h) performed on the 0.5%Ru/NiMo catalyst showed that this catalyst was less prone to deactivation than the NiMo reference sample. In the hydrotreatment of a SRGO (S = 0.55 wt%), the sulfide 0.5%Ru/NiMo/Al2O3 catalyst proved to be more active in the HDS and HDA reactions than a commercial NiMo/Al2O3 one.

Keywords

HCE

HPC