Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

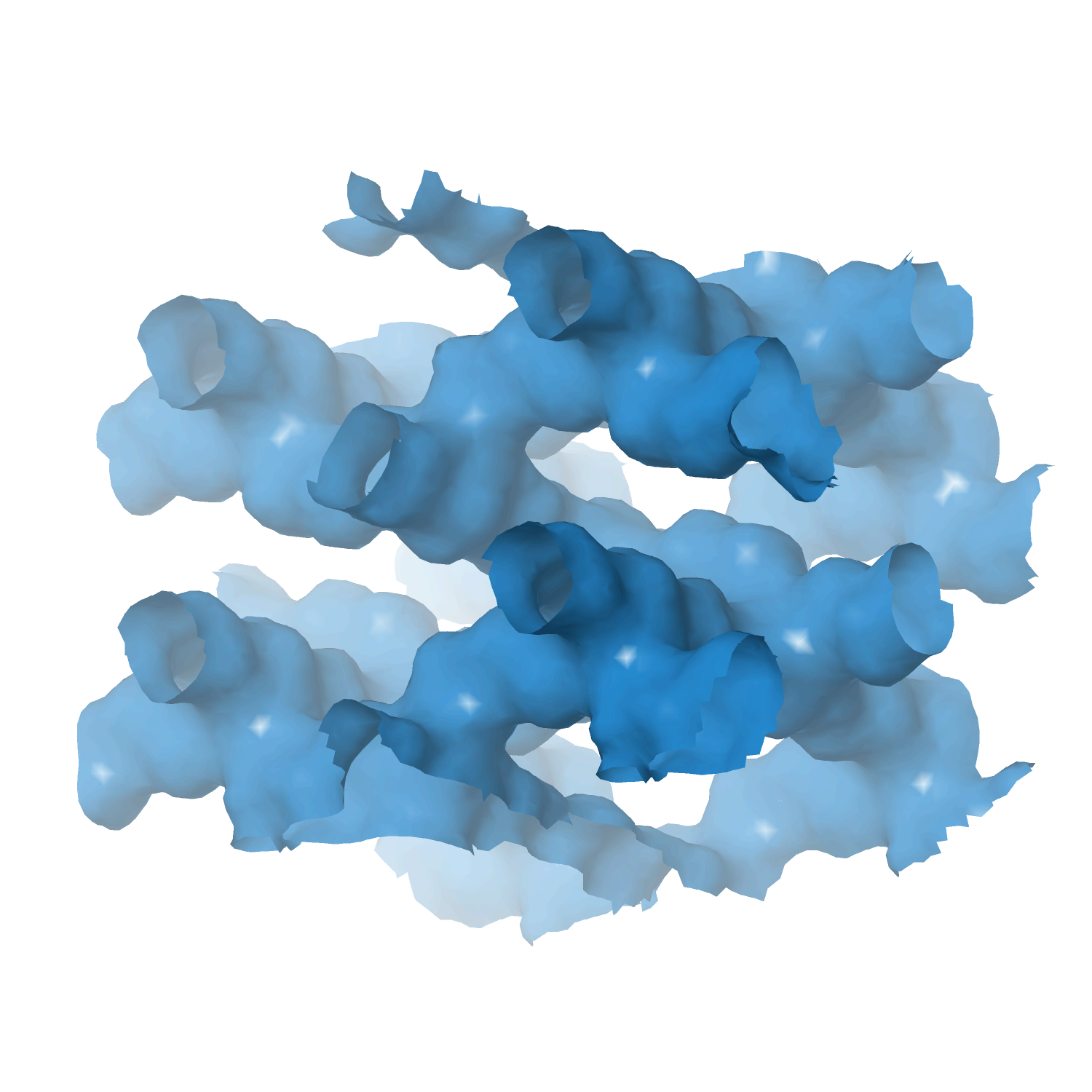

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Engineering Thermally Resistant Catalytic Particles for Oxidative Coupling of Methane Using Spray-Drying and Incorporating SiC

by

Lezcano, Velisoju, Kulkarni, Ramirez, Castaño

Ind. Eng. Chem. Res.

Year:

2021

Abstract

Oxidative coupling of methane (OCM) is a promising single-step route to convert natural gas to high-valued chemicals. It is generally agreed that Mn–Na–W catalysts offer a balanced conversion–selectivity trade-off. The present work outlines a novel SiC–SiO2 support synthesized by spray drying to extend the lifetime of the catalyst. Incorporating SiC into the support enables the exothermic reaction heat to be effectively dissipated, avoiding hotspots and thermal shocks, and increasing the thermal resistance. The spray drying technique yields particles with a consistent distribution of SiC inside the particles, amplifying the thermal resistance of the catalyst. Our kinetic results show that the spray dried catalyst with SiC has significantly higher stability at high C2selectivity compared to the benchmark SiO2-supported catalyst prepared by wetness impregnation. This result is due to (1) the more uniform distribution of active phases and SiC provided by the spray drying methodology and (2) the greater thermal resistance provided by SiC, which avoids thermal shocking and stabilizes the Mn–Na–W phases during the long-term (70 h) stability test for OCM.

Keywords

CHA

HCE