Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Elucidating the promoting role of Ca on PdZn/CeO2 catalyst for CO2 valorization to methanol

by

Zaman, Ojelade, Alhumade, Mazumder, Mohamed, Castaño

Fuel

Year:

2023

DOI:

https://doi.org/10.1016/j.fuel.2023.127927

Abstract

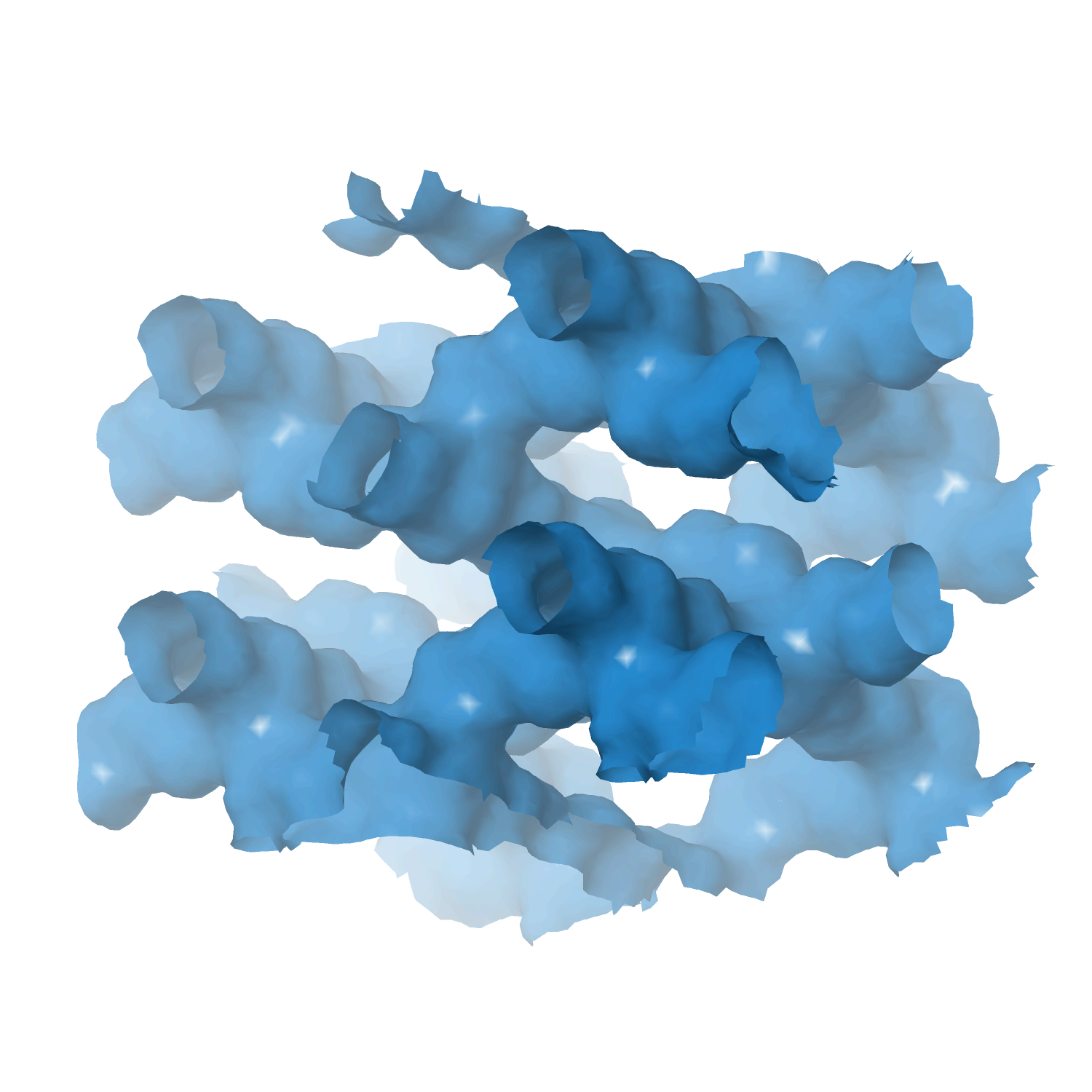

The viability of catalyzed CO2 conversion routes strongly depends on improving the catalytic performance and understanding of the process. Herein, we investigate the effect of Ca loading on PdZn/CeO2 catalysts prepared using the sol–gel chelatization method for CO2 hydrogenation to methanol. A remarkable improvement in catalyst performance was revealed with the optimum amount of Ca (0.5 wt%) in synergetic cooperation with the PdZn alloy (main active phase for the CO2 hydrogenation to methanol reaction), compared to the Ca-free counterpart. The following key performance indicators are attained at 230 °C, 20 bar, and 2400 h−1 GHSV for the optimized catalyst: 16 % CO2 conversion, > 93 % methanol selectivity, and ∼ 124 g/kgcat/h methanol space–time yield. The overall catalytic performance observed is attributed to the optimum Ce3+/Ce4+ ratio, Ca2+promotion, surface area, pore volume, and basic sites, as revealed by various characterization techniques. Results shown here indicate that the presence of Ca in the vicinity of the PdZn active enhances basicity, creates oxygen vacancies, and phase may have improved the spill-over ability of H2, consequently favoring CO2activation and methanol formation.

Keywords

CO2

HCE