Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

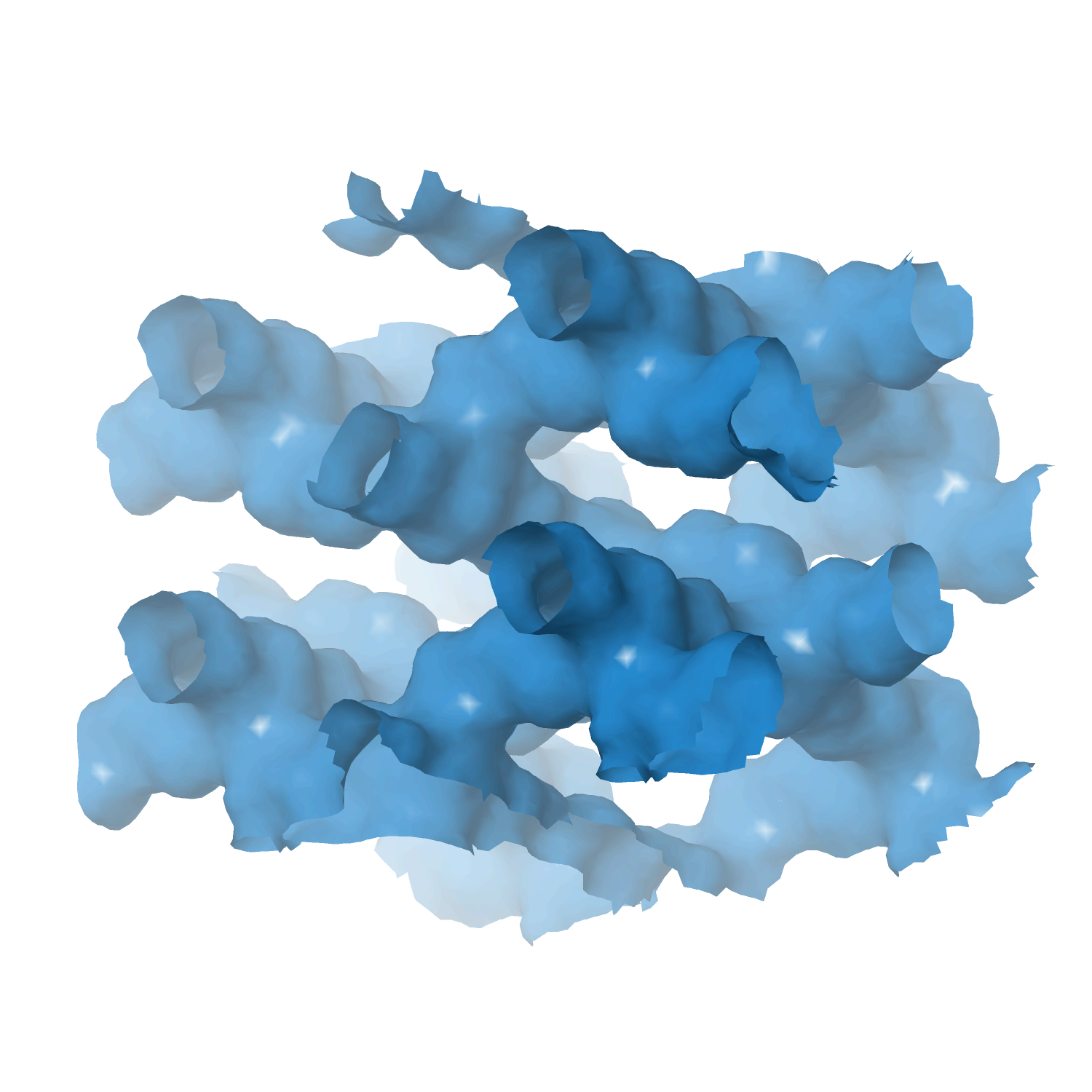

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Effect of the Support on the Kinetic and Deactivation Performance of Pt/Support Catalysts during Coupled Hydrogenation and Ring Opening of Pyrolysis Gasoline

by

Castaño, Gutierrez, Pawelec, Fierro, Aguayo, Arandes

Appl. Catal. A: Gen.

Year:

2007

Abstract

The upgrading of an aromatic-rich feedstock (pyrolysis gasoline) has been investigated over bifunctional Pt catalysts in order to evaluate the effect of the support on conversion, selectivity and deactivation. The experiments were conducted in a fixed-bed reactor at a pressure of 5 MPa and 350–450 °C. Pt was incorporated into five acidic supports: MFI, BEA and FAU zeolites, and an amorphous silica-alumina (ASA). Their surface properties and acidity were then assessed by means of several characterization techniques and related with their intrinsic activity–selectivity–deactivation. Using high hydrogen pressure (to minimize catalyst deactivation), we report the suitability of several catalysts for different purposes: Pt/MFI19 catalyst for a steam cracker feedstock production, Pt/BEA catalyst for isoalkane-rich gasoline pool manufacture and Pt/ASA catalyst for severe aromatic reduction while controlling the extent of ring scission. The results of accelerated deactivation experiments under low hydrogen pressure lead to the conclusion that MFI-supported catalysts (Pt/MFI19 and Pt/MFI95) yield less coke, but Pt/BEA deactivates to a lesser extent during hydrogenation.

Keywords

FCC

HCE

HPC