Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Designing a Multifunctional Catalyst for the Direct Production of Gasoline-Range Isoparaffins from CO2

by

Dokania, Ould-Chikh, Ramirez, Cerrillo, Aguilar, Russkikh, Alkhalaf, Hita, Bavykina, Shterk, Wehbe, Prat, Lahera, Castaño, Fonda, Hazemann, Gascon

JACS Au

Year:

2021

DOI:

https://doi.org/10.1021/jacsau.1c00317

Abstract

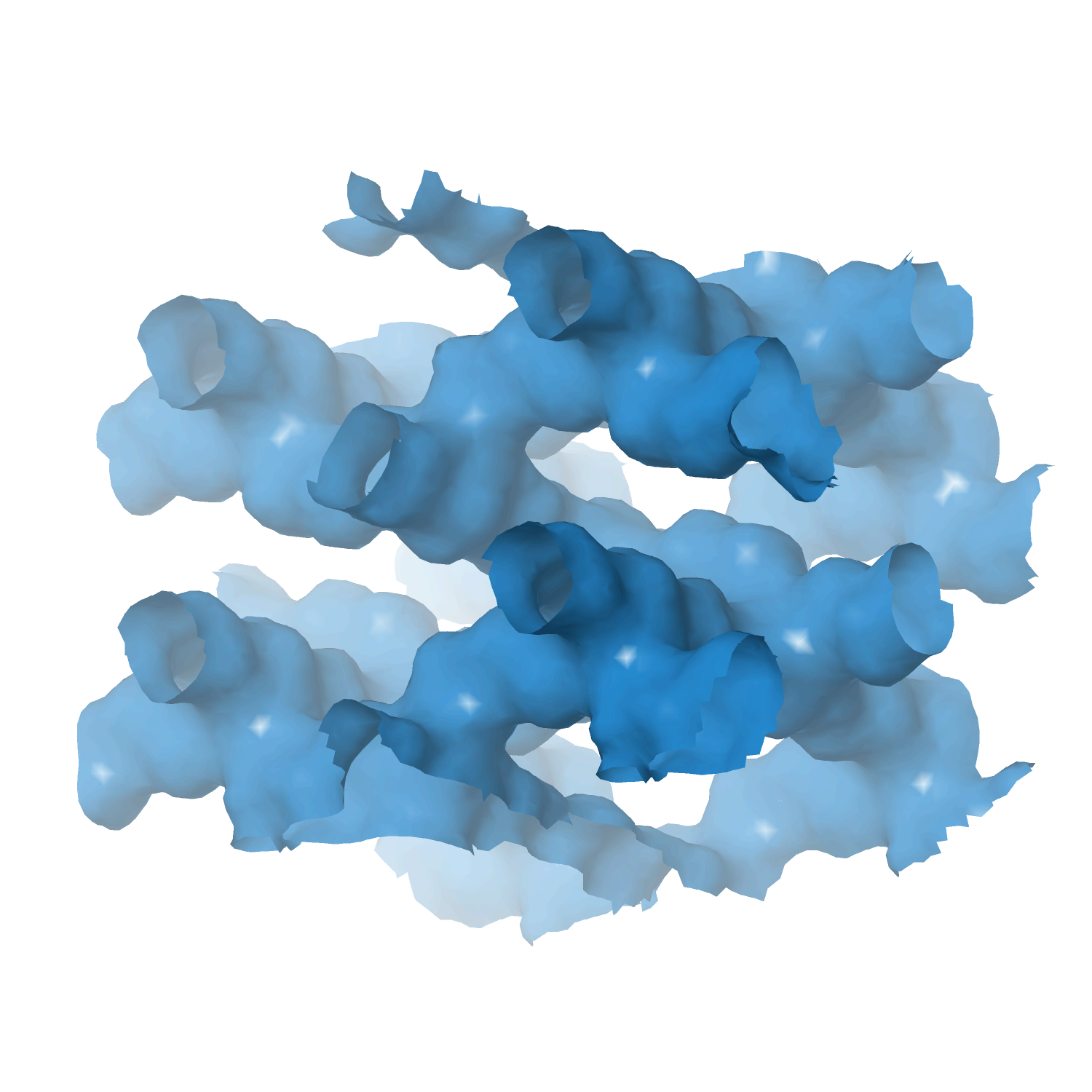

The production of carbon-neutral fuels from CO2 presents an avenue for causing an appreciable effect in terms of volume toward the mitigation of global carbon emissions. To that end, the production of isoparaffin-rich fuels is highly desirable. Here, we demonstrate the potential of a multifunctional catalyst combination, consisting of a methanol producer (InCo) and a Zn-modified zeolite beta, which produces a mostly isoparaffinic hydrocarbon mixture from CO2 (up to ∼85% isoparaffin selectivity among hydrocarbons) at a CO2 conversion of >15%. The catalyst combination was thoroughly characterized via an extensive complement of techniques. Specifically, operando X-ray absorption spectroscopy (XAS) reveals that Zn (which plays a crucial role of providing a hydrogenating function, improving the stability of the overall catalyst combination and isomerization performance) is likely present in the form of Zn6O6 clusters within the zeolite component, in contrast to previously reported estimations.

Keywords

CO2

HCE