Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Copper nanoparticles encapsulated in zeolitic imidazolate framework-8 as a stable and selective CO2 hydrogenation catalyst

by

Velisoju, Cerrillo, Ahmad, Yerrayya, Mohamed, Cheng, Yao, Zheng, Shekhah, Telalovic, Narciso, Cavallo, Eddaoudi, Ramos-Fernandez, Castaño

Nature Comm.

Year:

2024

DOI:

https://doi.org/10.1038/s41467-024-46388-4

Abstract

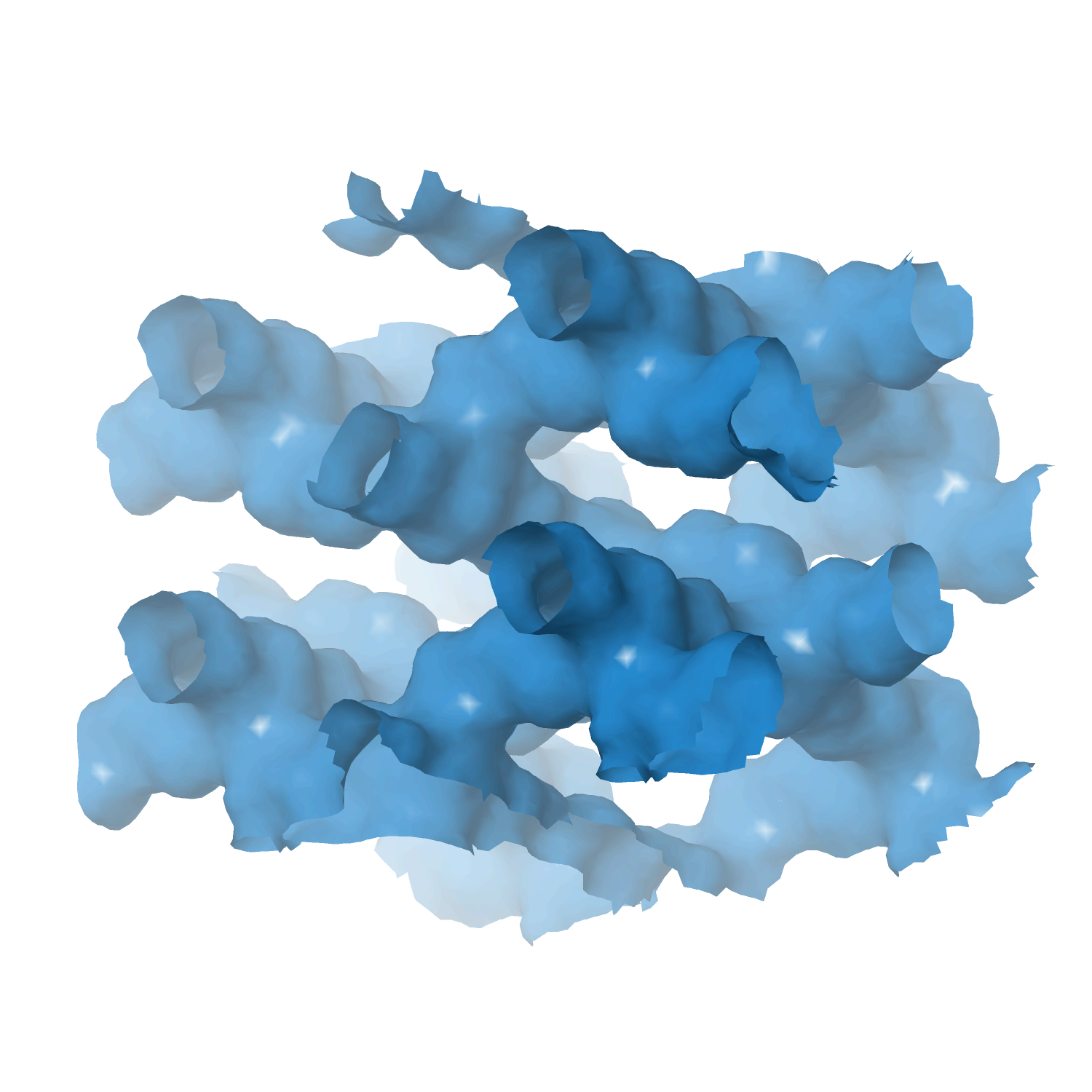

Metal–organic frameworks have drawn attention as potential catalysts owing to their unique tunable surface chemistry and accessibility. However, their application in thermal catalysis has been limited because of their instability under harsh temperatures and pressures, such as the hydrogenation of CO2 to methanol. Herein, we use a controlled two-step method to synthesize finely dispersed Cu on a zeolitic imidazolate framework-8 (ZIF-8). This catalyst suffers a series of transformations during the CO2 hydrogenation to methanol, leading to ~14 nm Cu nanoparticles encapsulated on the Zn-based MOF that are highly active (2-fold higher methanol productivity than the commercial Cu–Zn–Al catalyst), very selective (>90%), and remarkably stable for over 150 h. In situ spectroscopy, density functional theory calculations, and kinetic results reveal the preferential adsorption sites, the preferential reaction pathways, and the reverse water gas shift reaction suppression over this catalyst. The developed material is robust, easy to synthesize, and active for CO2 utilization.

Keywords

CO2

HCE