Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Gd–Modified Zn/ZSM-5 Catalysts With Suppressed Coke Formation for Methanol-to-Aromatics Conversion

by

Jayaseelan, Mohamed, Trueba, Velisoju, Morlanes, Genovese, Hedhili, Telalovic, Emwas, Castaño

ChemCatChem

Year:

2026

DOI:

https://doi.org/10.1002/cctc.202501499

Abstract

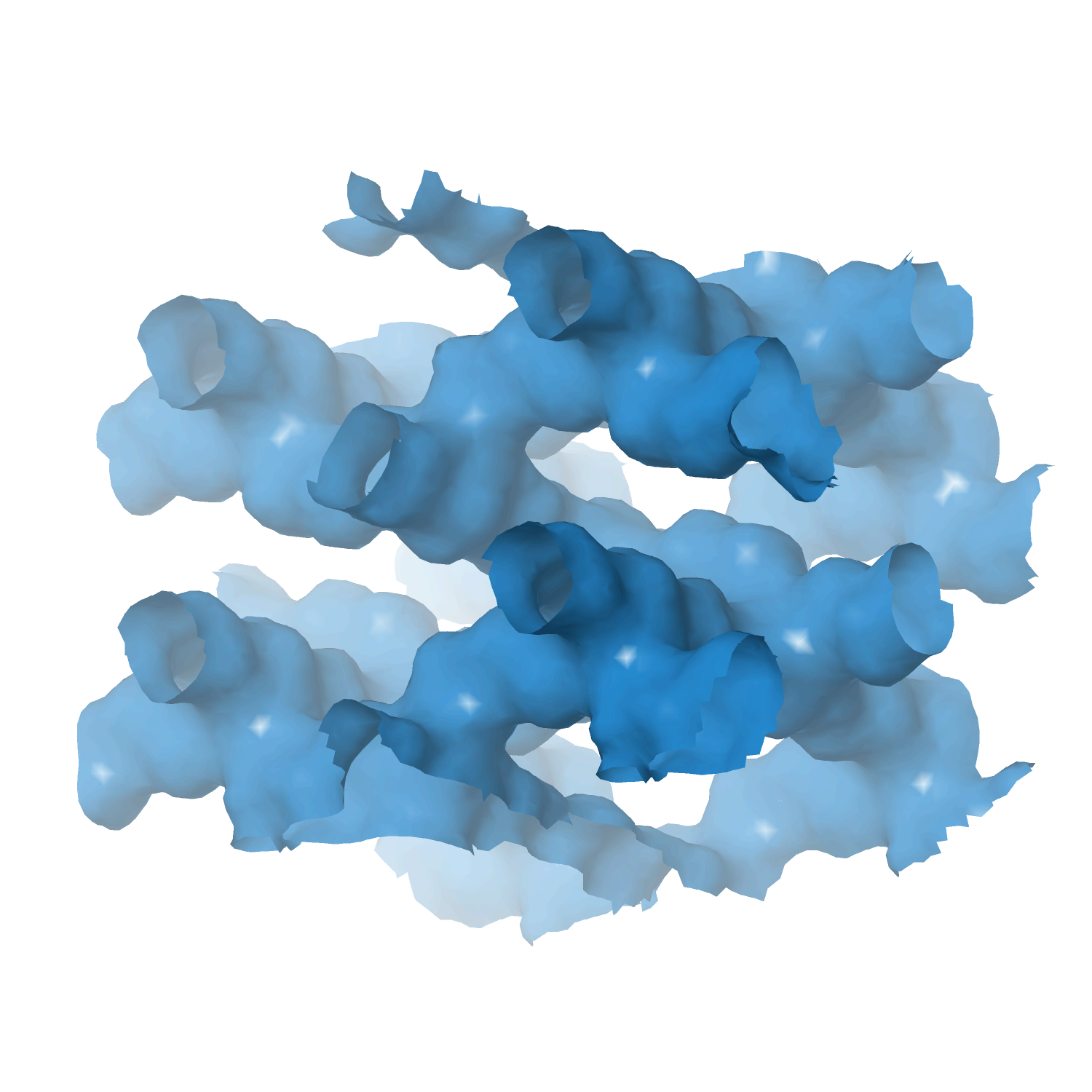

The conversion of methanol into aromatic hydrocarbons is fundamentally constrained by the competing formation of valuable aromatic products and polyaromatic coke, which rapidly deactivates zeolite catalysts. Here, we demonstrate that cooperative modification of ZSM-5 with a bimetallic system, zinc (Zn) and gadolinium (Gd), provides an effective strategy to overcome this limitation. Structural analyses using atomic-resolution electron microscopy, X-ray diffraction, X-ray fluorescence, and solid-state 27Al nuclear magnetic resonance confirm that both metals remain atomically dispersed on the external surfaces without altering the MFI framework. Acidity measurements show that Zn introduces dehydrogenation-active Lewisacid sites, while Gd moderates strong Brønsted acid sites. Operando ultraviolet–visible spectroscopy and multi-modal coke characterization reveal that Gd suppresses polyaromatic growth, whereas Zn enhances aromatic-ring formation. Their combination yields high aromatic productivity, minimal coke deposition, and exceptional operational stability for over 72 h. The bimetallic catalyst also demonstrates excellent regeneration capability over three consecutive cycles, establishing a robust metal–acid design strategy for durable methanol-to-aromatics conversion.

Keywords

O2H

HCE