Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

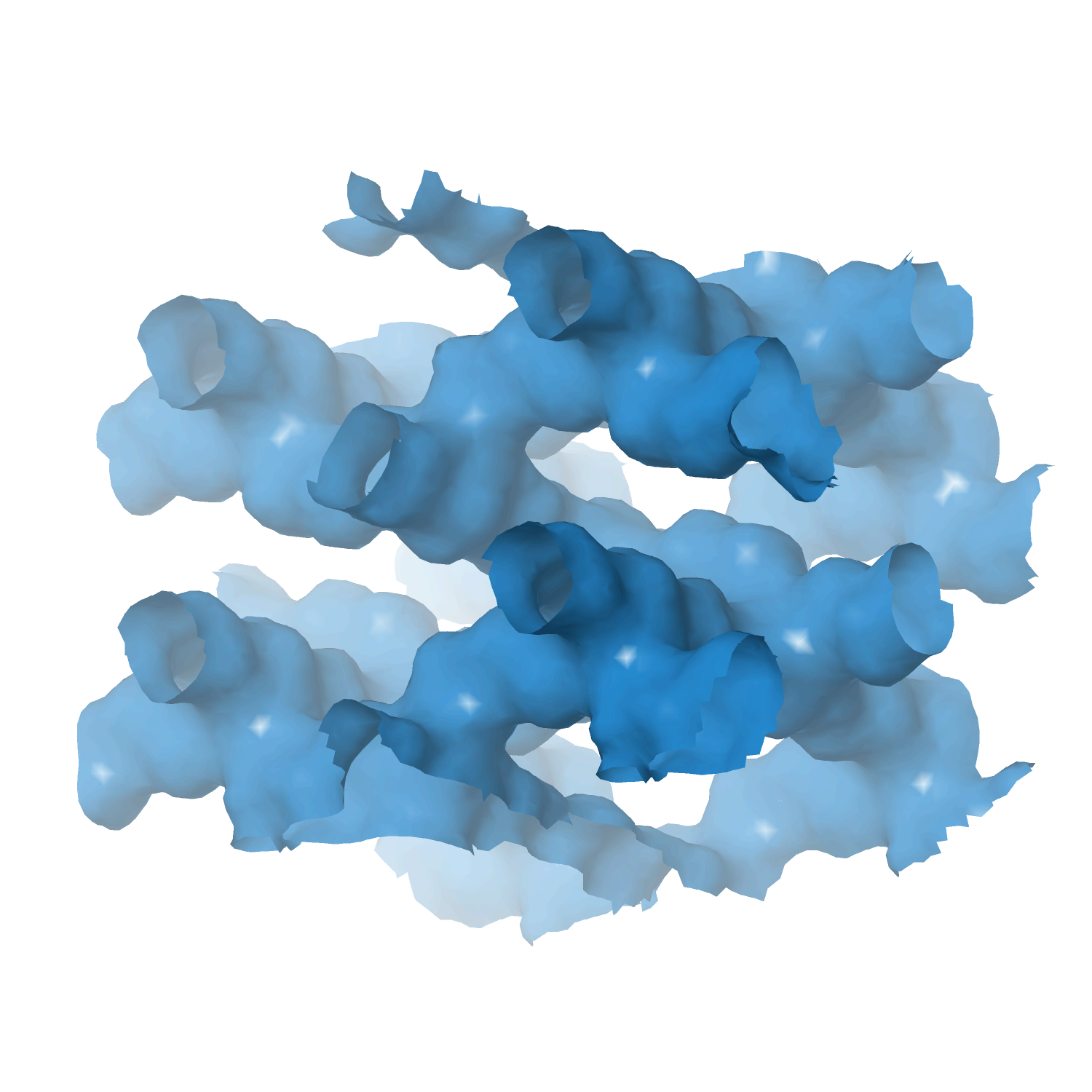

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Engineering Catalysts at the Multiscale: Past, Present, and Future of Catalyst Manufacturing and Shaping Processes

by

Alkadhem, Perez-Botella, Pietsch-Braune, Mohamed, Grande, Heinrich, Castaño

ChemCatChem

Year:

2026

DOI:

https://doi.org/10.1002/cctc.202501109

Abstract

Catalyst shaping is pivotal in optimizing catalytic performance across industrial chemical processes. The engineering of catalysts at multiple scales, ranging from nano to macro, has considerably evolved over the years, driven by advancements in shaping technology. We explore the progression of catalyst shaping, beginning with traditional methods, such as pelletizing and granulation, and advancing to modern techniques, including extrusion, spray-drying, fluidized-bed processes, and additive manufacturing (AM). This work emphasizes shaping technology tailored to specific reactor types, such as fixed-bed (up to structured catalyst) and fluidized-bed reactors. We highlight critical parameters to optimize and control catalyst properties and their direct influence on enhancing catalyst durability, activity, and selectivity. Advances in computational modeling, including multiscale simulations and machine learning-driven design, have further revolutionized catalyst shaping by enabling precise control and accelerating innovation. This review offers a comprehensive perspective on the future of multiscale catalyst shaping and underscores its potential to drive enhanced catalytic performance and sustainable chemical processes by analyzing historical developments, current trends, and emerging technology.

Keywords

CRE

HCE