Abstract

A kinetic model for the catalytic cracking of n-pentane over a HZSM-5 zeolite (Si/Al = 15) based catalyst has been proposed. In this model, the kinetic scheme of reactions is based on the paraffin cracking mechanisms and uses lumps (light olefins, light paraffins, C5+ paraffins, aromatics and methane). The reaction steps of the scheme are related with the catalytic cracking routes: protolytic cracking, β-scission, oligomerization-cracking, hydride transfer, olefin condensation and methane formation. In addition, a kinetic deactivation equation has been used for modeling the catalyst deactivation, depending on the coke precursors (light olefins and aromatics) concentration. The catalyst has been prepared by agglomerating the HZSM-5 zeolite with a mesoporous matrix of weak acidity, using pseudoboehmite as a binder. The kinetic runs have been carried out in a fixed bed reactor using the following conditions: 350–550 °C, 1.4 bar, space time up to 1.1 gcat h−1 molC−1 and time on stream up to 15 h. The formation of olefins and aromatics, as well as the catalyst deactivation, are favored at high temperatures. A mathematical methodology based on the Levenberg-Marquardt algorithm has been used for the kinetic parameters estimation. The method has allowed for the simultaneous computing of the kinetic parameters of each step of the reaction scheme and the deactivation kinetics, from the experimental results of evolution with the time on stream of each lump concentration.

Keywords

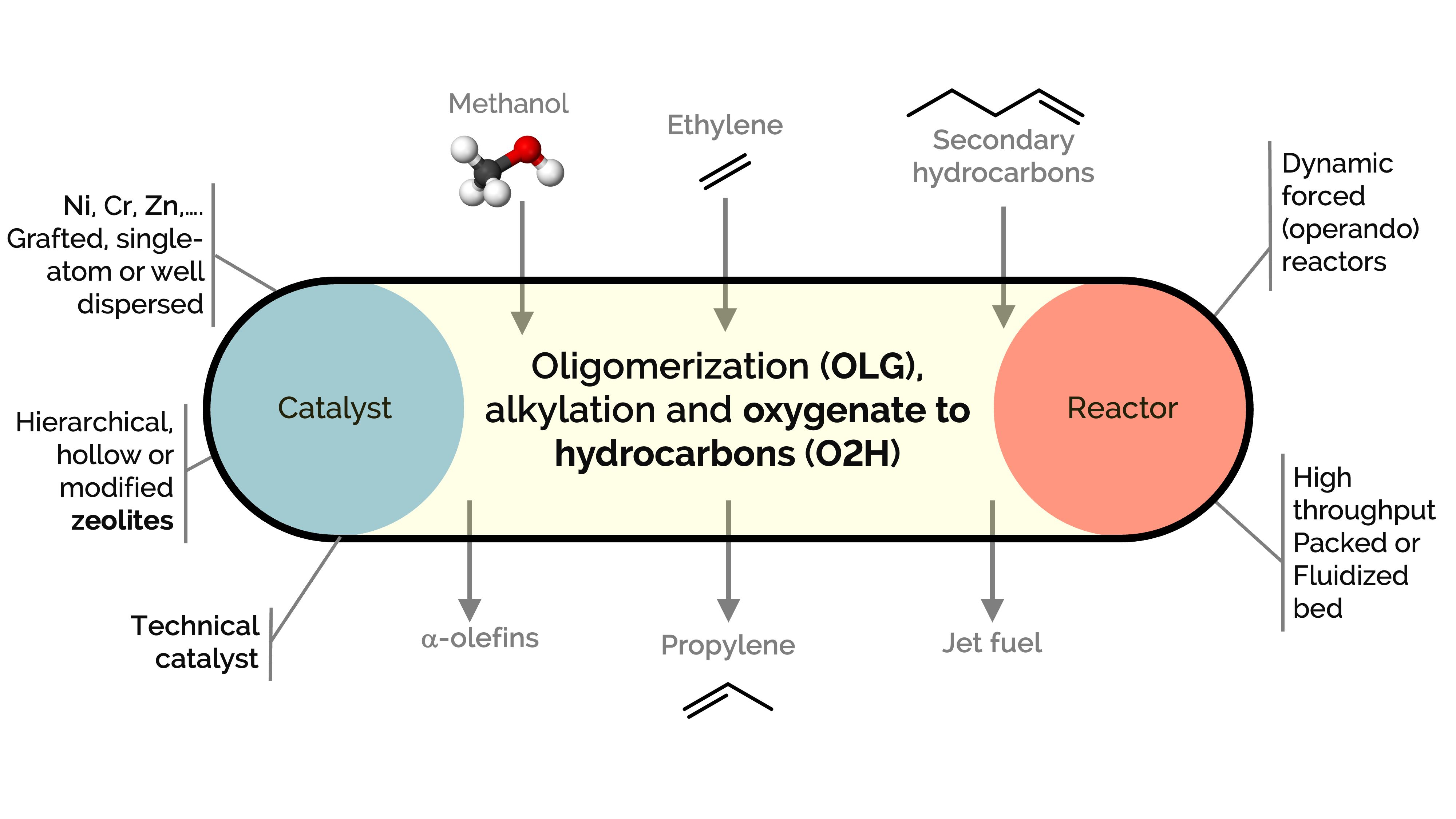

O2H

CHA

MKM