At lab-scale, the ultimate goal of a catalytic reactor is to provide (1) reliable kinetic information, neglecting or controlling other phenomena (heat-mass transfer and hydrodynamics); (2) high-throughput data to amplify the results, accelerate model and catalyst discoveries; and (3) results with the minimum requirements of reactants and wastes generated. The pillars of these reactors are quality, quantity, and safety.

We design, build and test different laboratory-scale reactors. Our strategy involves creating and testing reactor prototypes while modeling these using our workflow. We have high-speed cameras, probes, and other measuring instruments to understand the reactor behavior. We focus on packed-, fluidized-bed, and multiphase reactors:

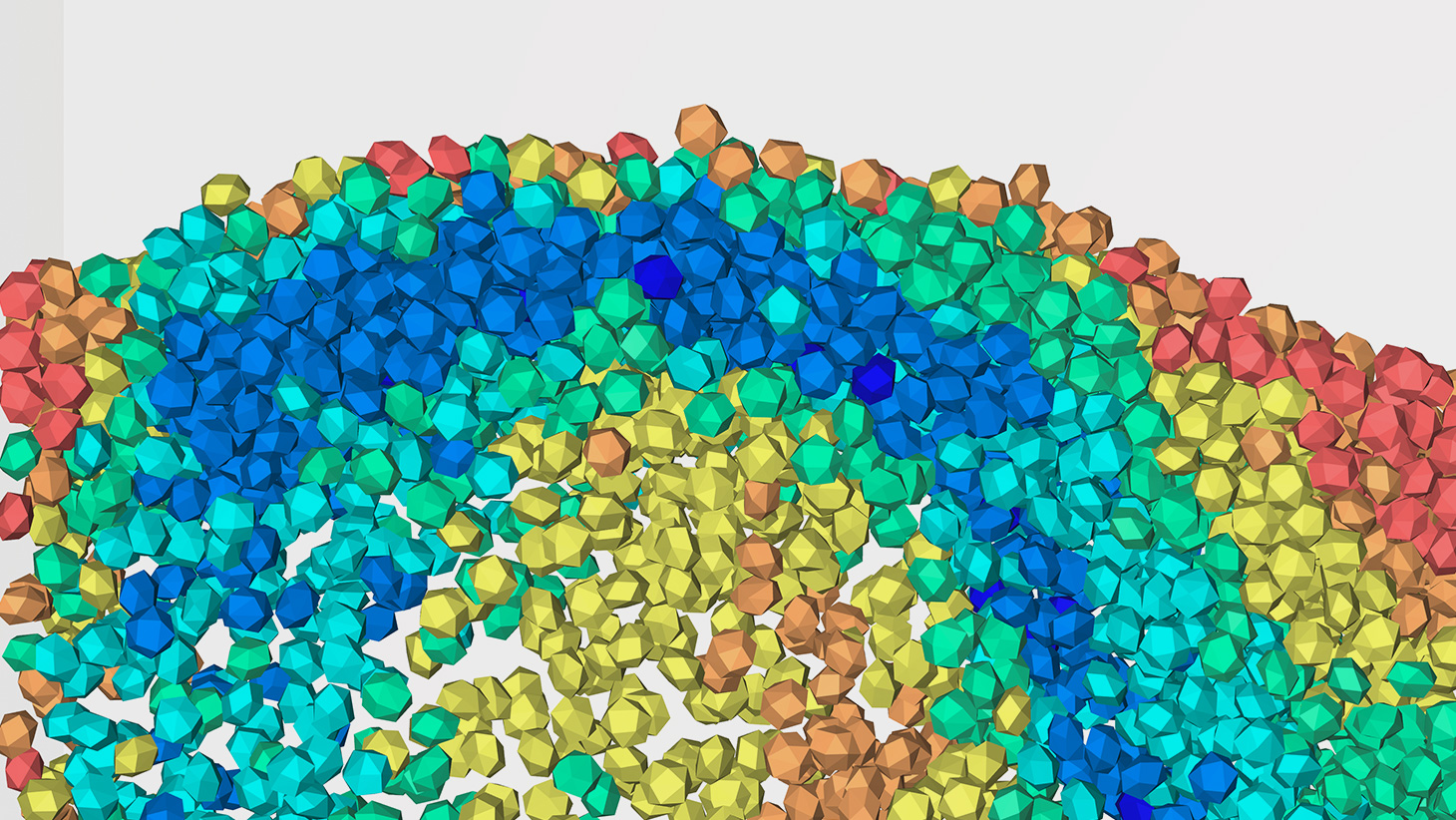

In packed bed reactors, we focus on forced dynamic and operando reactors. These are the quintessence of information-driven reactors where the dynamics can involve flow changes, temperature, pressure, partial pressure, presence of activity modifiers (poissons, H2O…). In operando reactors, we follow a spectro-kinetic-deactivation-hydrodynamic approach to resolve the individual steps involved. In fluidized bed reactors, we focus on downers and multifunctional reactors (circulating, multizone or two-zone, Berty reactors) We focus on trickle-bed, slurry, and bio-electrochemical reactors in multiphase bed reactors.

Al pilot-plant scale, we aim to reach the maximum productivity levels while solving the growing pains: the scale-up. Based on a robust kinetic model obtained in the intrinsic kinetic reactor (lab-scale) and using computational fluid dynamics, we design, build, and operate pilot plants. At this stage, we seek partnerships with investment or industrial enterprises to make these pilot plants.