At lab-scale, the ultimate goal of a catalytic reactor is to provide (1) reliable kinetic information, neglecting or controlling other phenomena (heat-mass transfer and hydrodynamics); (2) high-throughput data to amplify the results, accelerate model and catalyst discoveries; and (3) results with the minimum requirements of reactants and wastes generated. The pillars of these reactors are quality, quantity, and safety.

We design, build and test different laboratory-scale reactors. Our strategy involves creating and testing reactor prototypes while modeling these using our workflow. We have high-speed cameras, probes, and other measuring instruments to understand the reactor behavior. We focus on packed-, fluidized-bed, and multiphase reactors:

In packed bed reactors, we focus on forced dynamic and operando reactors. These are the quintessence of information-driven reactors where the dynamics can involve flow changes, temperature, pressure, partial pressure, presence of activity modifiers (poissons, H2O…). In operando reactors, we follow a spectro-kinetic-deactivation-hydrodynamic approach to resolve the individual steps involved. In fluidized bed reactors, we focus on downers and multifunctional reactors (circulating, multizone or two-zone, Berty reactors) We focus on trickle-bed, slurry, and bio-electrochemical reactors in multiphase bed reactors.

Al pilot-plant scale, we aim to reach the maximum productivity levels while solving the growing pains: the scale-up. Based on a robust kinetic model obtained in the intrinsic kinetic reactor (lab-scale) and using computational fluid dynamics, we design, build, and operate pilot plants. At this stage, we seek partnerships with investment or industrial enterprises to make these pilot plants.

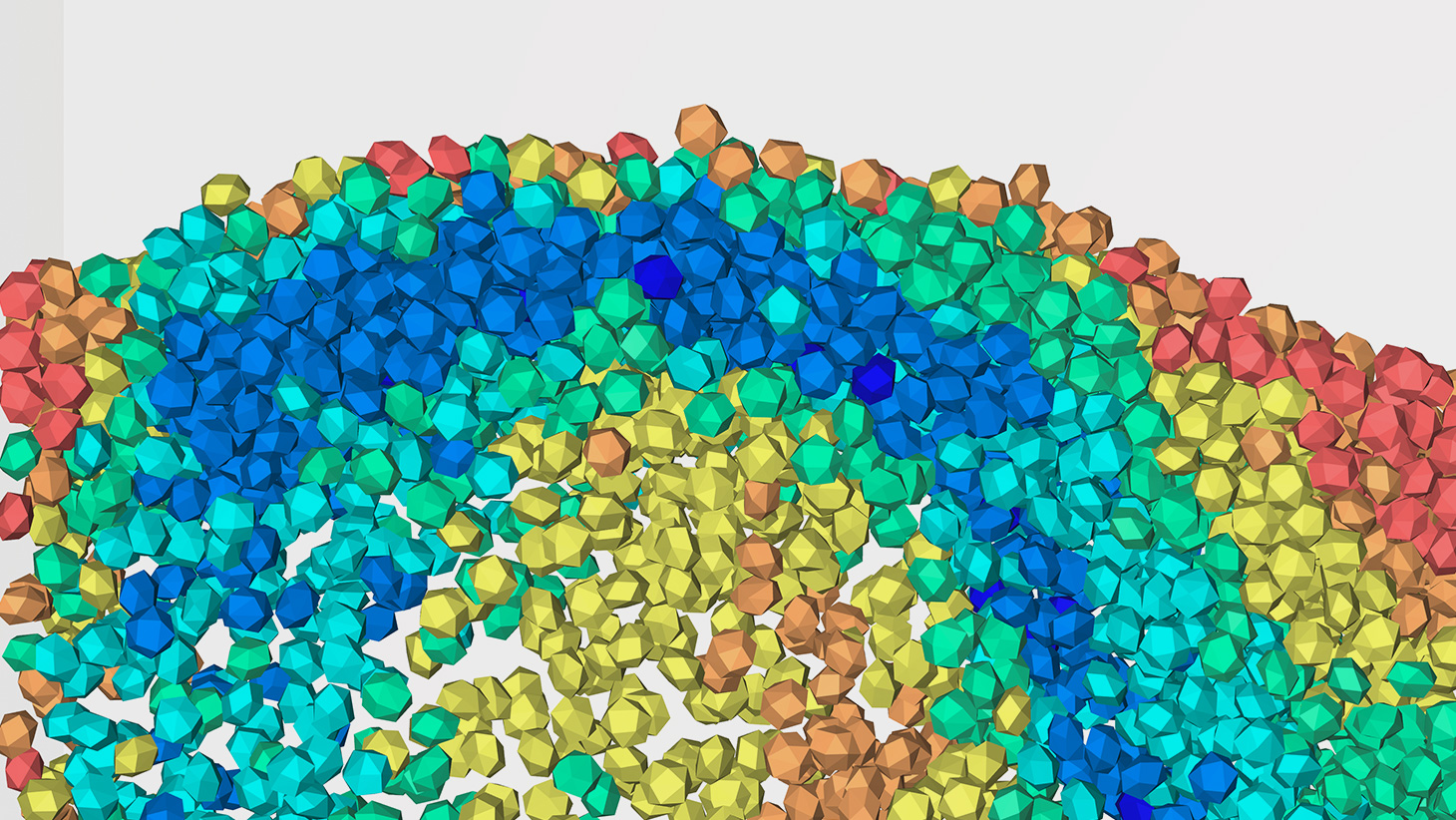

The optimal loading protocol of a microreactor (catalyst and inert: 0.1 mm, column: 2 mm internal diameter) with a catalyst–inert mixture is fundamentally different from that of a conventional lab-scale reactor (typical values: catalyst, 2 mm; inert, 0.2 mm; column, 10 mm internal diameter). This is shown to be due to segregation, occurring during loading. The following loading procedure has been used: premix the powders, funnel the mixture down, drop it within the reactor, and densify the bed. The average time a particle takes, from the mixing vial to reach its final position, depends on its properties, which in general results in an axially segregated bed. Radial segregation is observed for particles smaller than 60 m, as a result of electrostatic forces.

This paper describes for each handling step how to minimise segregation during the loading of a catalyst–diluent solid mixture. This includes using a funnel with a low-friction and steep wall, minimising difference in velocity of particle-gravity flow, and adding more inert after the mixture, prior to the densification step. The term is shown to sufficiently predict segregation due to the velocity difference during gravity flow. Segregation can be observed relatively easily in a glass mock-up reactor. Optimising all the handling steps to minimise segregation results in a visually homogeneous bed.