Heterogeneous catalyst engineering ⇒ from stable and deactivation resistant to viable technical catalyst

Advances in heterogeneous catalyst “structure” are driven to improve their “function” or performance, i.e., activity, selectivity, and stability. Cooperative research is required to understand the structure and function relationships: developing new synthesis protocols for heterogeneous catalysts with unique surface properties, defined porosity, identification and understanding of catalytically active sites, reaction mechanisms, and finally, prediction and analysis of the processes using various computational tools.

Our group focuses on developing new catalyst formulations using innovative synthesis routes for various important heterogeneous catalysts. That includes thermal, electro, and bio-electro catalysis.

The active phase cannot be used directly in its final application or reactor for various reasons, including poor mechanical resistance, heat or mass transport, and fluidization features. We must mix the active phase with other ingredients in a matrix of binder and filler, while we shape it into a technical catalyst. We investigate new synthetic protocols for technical catalysis using spray drying and fluidized beds to cover the whole range of sizes. At the same time, we incorporate additional (unconventional) ingredients such as SiC to improve some features even further.

- Technical catalyst I ⇒ spray drying and extrusion

- Technical catalyst II ⇒ spray fluidized bed reactor

- Technical catalyst III ⇒ electrospinning

- Zeolite catalysts ⇒ with defined structure/porosity

- Multi-metal (high entropy) alloy catalysts

- MXene catalysts ⇒ single and multi-dimensional

- Perovskite catalysts

- Metal-organic framework (MOFs) catalysts

- Supported metal/metal-oxide catalysts

- Aerogel catalyst

Illuminating the Intrinsic Effect of Water Co-feeding on Methane Dehydroaromatization: A Comprehensive Study

by

Çaǧlayan, Lucini Paioni, Dereli, Shterk, Hita, Abou-Hamad, Pustovarenko, Emwas, Dikhtiarenko, Castaño, Cavallo, Baldus, Chowdhury, Gascon

ACS Catal.

Year:

2021

DOI:

https://doi.org/10.1021/acscatal.1c02763

Abstract

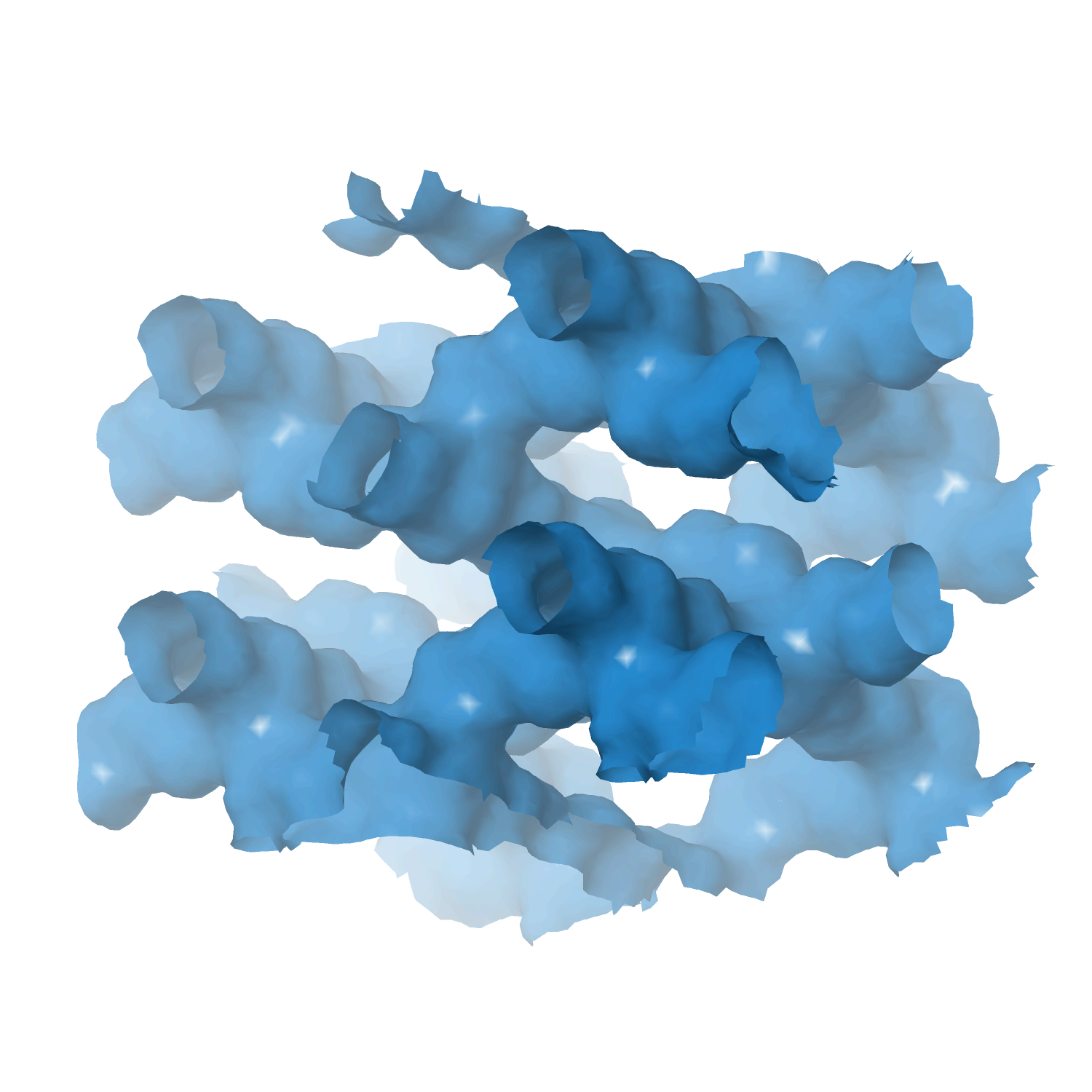

Among all catalytic natural gas valorization processes, methane dehydroaromatization (MDA) still has a great potential to be utilized at an industrial level. Although the use of Mo/H-ZSM-5 as an MDA catalyst was first reported almost three decades ago, the process is yet to be industrialized, because of its inherent challenges. In order to improve the overall catalytic performance and lifetime, the co-feeding of water constitutes a promising option, because of its abundance and nontoxicity. Although water’s (limited) positive influence on catalyst lifetime has earlier been exhibited, the exact course of action (like mechanism or the water effect on active sites) is yet to be established. To bridge this knowledge gap, in this work, we have performed an in-depth investigation to elucidate the effects of water co-feeding over a well-dispersed Mo/H-ZSM-5 catalyst by using an array of advanced characterization techniques (nuclear magnetic resonance (NMR), electron paramagnetic resonance (EPR), X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), thermogravimetry–temperature-programmed oxidation/mass spectroscopy (TG-TPO/MS), scanning transmission electron microscopy (STEM), N2 physisorption, Raman spectroscopy, inductively coupled plasma–optical emission spectroscopy (ICP-OES)). Our results demonstrate that the addition of water results in the occurrence of steam reforming (of both coke and methane) in parallel to MDA. Moreover, the presence of water affects the reducibility of Mo sites, as corroborated with computational analysis to examine the state and locality of Mo sites under various water levels and transformation of the catalyst structure during deactivation. We anticipate that our comprehensive study of the structure–function relationship on Mo/H-ZSM-5 under humid MDA conditions will be beneficial for the development of future methane valorization technologies.

Keywords

CHA

HCE