Abstract

A family of unprecedented supramolecularly assembled porous metal–organic compounds (SMOFs), based on [Cu6M(μ-adeninato)6(μ3-OH)6(μ-H2O)6]2+ cations (MII: Cu, Co, Ni, and Zn) and different dicarboxylate anions (fumarate, benzoate, and naphthalene-2,6-dicarboxylate), have been employed as precursors of catalysts for the thermocatalytic reduction of CO2. The selected metal–organic cation allows us to tune the composition of the SMOFs and, therefore, the features and performance of the final homometallic and bimetallic catalysts. These catalysts were obtained by thermolysis at 600 °C under a N2 atmosphere and consist of big metal particles (10–20 μm) placed on the surface of the carbonaceous matrix and very tiny metal aggregates (<10 nm) within this carbonaceous matrix. The latter are the most active catalytic sites for the CO2 thermocatalytic reduction. The amount of this carbonaceous matrix correlates with the organic content present in the metal–organic precursor. In this sense, CO2 thermocatalytic reduction experiments performed over the homometallic, copper only, catalysts with different carbon contents indicate that above a certain value, the increase of the carbonaceous matrix reduces the overall performance by encapsulating the nanoparticles within this matrix and isolating them from interacting with CO2. In fact, the best performing homometallic catalyst is that obtained from the precursor containing a small fumarate counterion. On the other hand, the structural features of these precursors also provide a facile route to work with a solid solution of nanoparticles as many of these metal–organic compounds can replace up to 1/7 of the copper atoms by zinc, cobalt, or nickel. Among these heterometallic catalysts, the best performing one is that of copper and zinc, which provides the higher conversion and selectivity toward CO. XPS spectroscopy and EDX mappings of the latter catalyst clearly indicate the presence of Cu1–xZnx nanoparticles covered by small ZnO aggregates that provide a better CO2 adsorption and easier CO release sites.

Keywords

CRE

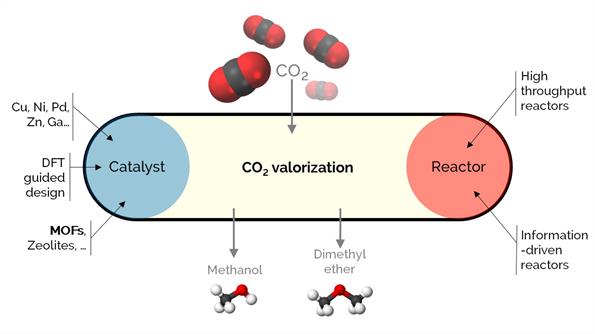

CO2