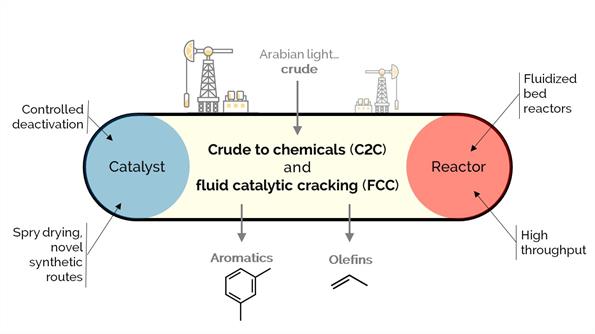

The direct catalytic cracking from crude oil to chemicals could dominate the petrochemical industry shortly, with less fuel consumption and increasing production of light olefins and aromatics. We aim to simplify the refinery into a unique one-step conversion scheme, targeting the production of the most demanded petrochemicals.

Using a bottom-up holistic approach, we design a catalytic crude-to-chemicals process toward this goal using a bottom-up holistic approach. We investigate advanced reactors with intrinsic kinetic data and controlled hydrodynamics to improve the process. We study the non-linear multiscale phenomena by coupling the hydrodynamics, heat transfer, and reaction kinetics.

We use particle image/tracking velocimetry experiments, kinetic modeling, computational particle fluid dynamic modeling, and optimization approaches to improve operating scenarios and develop innovative reactor prototypes.

We focus on the catalyst, reactor, and process levels for system enhancement and intensification. We are optimizing several state-of-the-art laboratory and pilot-scale units, including a circulating Berty, downer, and multifunctional fluidized bed reactors.